Admin

مدير المنتدى

عدد المساهمات : 18864

التقييم : 35108

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

|  موضوع: كتاب The Basics of Hydraulic Systems موضوع: كتاب The Basics of Hydraulic Systems  الثلاثاء 24 مايو 2022, 2:35 am الثلاثاء 24 مايو 2022, 2:35 am | |

|

أخواني في الله

أحضرت لكم كتاب

The Basics of Hydraulic Systems

و المحتوى كما يلي :

TABLE OF CONTENTS

Section Page

Subcourse Overview . i

Administrative Instructions . iv

Grading and Certification Instructions iv

Lesson 1: Basic Hydraulics . 1

Practice Exercise . 19

Answer Key and Feedback . 22

Lesson 2: Hydraulic Plumbing 25

Practice Exercise . 69

Answer Key and Feedback . 71

Appendix A: Proof Testing of Hose Assemblies 72

Appendix B: Glossary 73

Examination . 78

Student Inquiry Sheet

Hydraulics

Table of Contents

Page

LIST OF FIGURES AND TABLES vii

Figures vii

Tables . xiii

PREFACE . xiv

CHAPTER 1. Hydraulic Basics . 1-1

1-1. Pressure and Force . 1-1

Pressure . 1-1

Force . 1-3

1-2. Pascal’s Law . 1-4

1-3. Flow . 1-6

Velocity . 1-6

Flow Rate . 1-6

1-4. Energy, Work, and Power . 1-6

Potential Energy . 1-6

Kinetic Energy . 1-6

Heat Energy and Friction . 1-6

Relationship Between Velocity and Pressure . 1-7

Work . 1-8

Power . 1-8

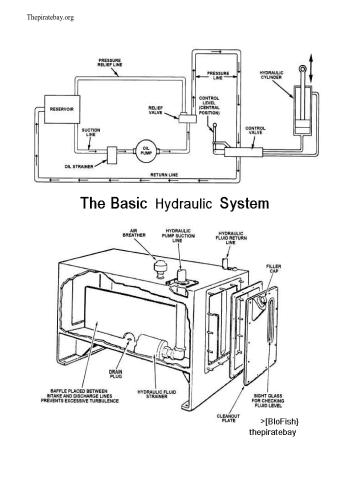

CHAPTER 2. Hydraulic Systems . 2-1

2-1. Basic Systems . 2-1

Hydraulic Jack . 2-1

Motor-Reversing System 2-1

Open-Center System . 2-2

Closed-Center System . 2-5

OS-Software OS-Software

iFM 5-499

ii

Page

2-2. Color Coding 2-9

2-3. Reservoirs 2-9

Construction 2-9

Shape . 2-10

Size 2-10

Location . 2-10

Ventilation and Pressurization 2-11

Line Connections . 2-11

Maintenance . 2-11

2-4. Strainers and Filters 2-11

Strainers 2-12

Filters 2-12

2-5. Filtering Material and Elements . 2-14

2-6. Accumulators . 2-14

Spring-Loaded Accumulator 2-14

Bag-Type Accumulator . 2-15

Piston-Type Accumulator . 2-15

Maintenance . 2-15

2-7. Pressure Gauges and Volume Meters . 2-17

Pressure Gauges 2-17

Meters 2-17

2-8. Portable Hydraulic-Circuit Testers . 2-18

Testers 2-18

Improper Operation . 2-18

2-9. Circulatory Systems . 2-18

Tubing 2-19

Piping 2-19

Flexible Hosing . 2-19

Installation 2-21

2-10.Fittings and Connectors 2-21

Threaded Connectors 2-21

Flared Connectors . 2-23

Flexible-Hose Couplings 2-25

Reusable Fittings . 2-25

2-11.Leakage . 2-29

Internal . 2-29

External . 2-30

Prevention . 2-30

2-12.Seals 2-30

Static Seals 2-31

Dynamic Seals . 2-31

Packing . 2-33

Seal Materials 2-34FM 5-499

iii

Page

CHAPTER 3. Pumps . 3-1

3-1. Pump Classifications . 3-1

Nonpositive-Displacement Pumps 3-1

Positive-Displacement Pumps 3-1

Characteristics 3-2

3-2. Performance 3-2

3-3. Displacement . 3-2

Fixed-Displacement Pump . 3-3

Variable-Displacement Pump 3-3

3-4. Slippage 3-3

3-5. Designs 3-3

Centrifugal Pump 3-3

Rotary Pump 3-4

Reciprocating Pump 3-4

3-6. Gear Pumps 3-4

External . 3-4

Internal 3-5

Lobe Pump . 3-6

3-7. Vane Pumps 3-6

Characteristics 3-6

Unbalanced Vane Pumps 3-6

Balanced Vane Pumps 3-7

Double Pumps 3-7

Two-Stage Pumps 3-9

3-8. Piston Pumps 3-10

Radial 3-10

Axial Piston Pumps . 3-11

3-9. Pump Operation 3-14

Overloading . 3-14

Excess Speed 3-14

Cavitation . 3-14

Operating Problems . 3-15

CHAPTER 4. Hydraulic Actuators . 4-1

4-1. Cylinders . 4-1

Single-Acting Cylinder 4-1

Double-Acting Cylinder . 4-1

Differential Cylinder . 4-1

Nondifferential Cylinder 4-2

Ram-Type Cylinder 4-2

Piston-Type Cylinder . 4-3

Cushioned Cylinder 4-4

Lockout Cylinders . 4-4

4.2 Construction and Application 4-4FM 5-499

iv

Page

4-3. Maintenance 4-5

External Leakage 4-5

Internal Leakage 4-5

Creeping Cylinder 4-5

Sluggish Operation . 4-5

Loose Mounting . 4-5

Misalignment . 4-5

Lack of Lubrication . 4-7

Abrasives on a Piston Rod . 4-7

Burrs on a Piston Rod 4-7

Air Vents . 4-7

4-4. Hydraulic Motors 4-7

Gear-Type Motors 4-8

Vane-Type Motors 4-8

Piston-Type Motors 4-10

CHAPTER 5. Valves . 5-1

5-1. Pressure-Control Valves . 5-1

Relief Valves 5-2

Pressure-Reducing Valves . 5-3

Sequence Valves . 5-5

Counterbalance Valves 5-7

Pressure Switches 5-8

5-2. Directional-Control Valves . 5-8

Poppet Valve 5-9

Sliding-Spool Valve 5-10

Check Valves . 5-10

Two-Way Valve . 5-14

Four-Way Valves . 5-14

5-3. Flow-Control Valves . 5-19

Gate Valve . 5-19

Globe Valve 5-21

Needle Valve . 5-22

Restrictor 5-22

Orifice Check Valve . 5-23

Flow Equalizer . 5-23

5-4. Valve Installation . 5-25

Meter-In Circuit 5-25

Meter-Out Circuit . 5-25

Bleed-Off Circuit 5-26

Compensated Flow 5-26

5-5. Valve Failures and Remedies 5-26

Servicing Valves 5-27

Disassembling Valves 5-27

Repairing Valves 5-28FM 5-499

v

Page

5-6. Valve Assembly . 5-29

5-7. Troubleshooting Valves 5-30

Pressure-Control Valves . 5-30

Directional-Control Valves . 5-32

Volume-Control Valves 5-33

CHAPTER 6. Circuit Diagrams and Troubleshooting . 6-1

6-1. Hydraulic-Circuit Diagrams . 6-1

6-2. United States of American Standards Institute (USASI) Graphical . 6-1

Symbols

Reservoir . 6-4

Lines 6-4

Pump 6-4

Motor 6-5

Cylinder . 6-5

Pressure-Control Valves 6-5

Flow-Control Valves 6-7

Directional-Control Valves 6-7

Accessories . 6-9

6-3. Typical Mobile Circuits 6-11

Hydraulic-Lift Circuit . 6-11

Power-Steering Circuits 6-12

Road-Patrol-Truck Circuits . 6-12

6-4. Troubleshooting 6-13

Causes of Improper Operations 6-13

Testing a Hydraulic Circuit . 6-13

Comparing Test Results with Specifications . 6-13

Slippage 6-15

Flow and Pressure 6-15

Other Conditions . 6-15

Specific Troubles, Causes, and Solutions 6-16

CHAPTER 7. Electrical Devices: Troubleshooting and Safety . 7-1

7-1. Hydraulics and Electricity . 7-1

7-2. Troubleshooting Electrical Devices 7-1

Procedure 7-5

Testing Devices . 7-6

7-3. Ground 7-8

Earth Ground . 7-8

Chassis or Common Ground . 7-9

Zero Reference Point . 7-9

Isolation Between Earth and Chassis Ground 7-10

7-4. Safety 7-10

Information 7-10

Practices 7-11FM 5-499

vi

Page

APPENDIX A. Metric Conversion Chart . Appendix-1

GLOSSARY Glossary-1

REFERENCES . References-1

INDEX . Index-1

TABLE OF CONTENTS

Section Page

Subcourse Overview . i

Terminal Learning Objective . ii

Administrative Instructions . iv

Grading and Certification Instructions iv

Lesson 1: Hydraulic Reservoirs, Filters, Pumps,

Accumulators, and Motors 1

Practice Exercise . 19

Answer Key and Feedback . 22

Lesson 2: Basic Construction and Operation of Hydraulic

Actuating Devices, Flow Control, and Directional

Devices . 25

Practice Exercise . 43

Answer Key and Feedback . 46

Lesson 3: Hydraulic Pressure-Limiting, Controlling, and

Sensing Devices . 49

Practice Exercise . 55

Answer Key and Feedback . 58

Examination 61

Appendix: Glossary . 69

Student Inquiry Sheets

Engineering and Design

DESIGN OF HYDRAULIC STEEL

STRUCTURES

Table of Contents

Subject Paragraph Page Subject Paragraph Page

Chapter 1 Commentary on Paragraph 3-4,

Introduction Reliability Factors for HSS . 3-8 3-2

Purpose 1-1 1-1 Commentary on Paragraph 3-6, Fatigue

Applicability 1-2 1-1 and Fracture Control 3-9 3-3

References 1-3 1-1

Background . 1-4 1-1 Chapter 4

Commentary on Paragraph 1-4, Allowable Stress Design

Background 1-5 1-1 General . 4-1 4-1

Design Basis . 4-2 4-1

Chapter 2 Load and Stress Requirements . 4-3 4-1

General Considerations HSS Types: Modifications for

Limit States 2-1 2-1 Allowable Stresses . 4-4 4-1

Corrosion 2-2 2-1 Serviceability Requirements 4-5 4-1

Dynamic Loading 2-3 2-1 Fatigue and Fracture Control . 4-6 4-1

Inspection and Maintenance 2-4 2-1 Commentary on Paragraph 4-3, Load and

Deviations from Prescribed Stress Requirements . 4-7 4-2

Design 2-5 2-1 Commentary on Paragraph 4-4, HSS Types:

Commentary on Paragraph 2-2, Modifications for Allowable

Corrosion 2-6 2-1 Stresses 4-8 4-2

Commentary on Paragraph 2-3, Dynamic

Loading 2-7 2-2 Chapter 5

Connections and Details

Chapter 3 General . 5-1 5-1

Load and Resistance Factor Design Design Considerations 5-2 5-1

General . 3-1 3-1 Bolted Connections 5-3 5-1

Design Basis . 3-2 3-1 Welded Connections . 5-4 5-1

Strength Requirements 3-3 3-1 Commentary on Paragraph 5-1,

Reliability Factors for HSS 3-4 3-1 General 5-5 5-1

Serviceability Requirements 3-5 3-1 Commentary on Paragraph 5-2,

Fatigue and Fracture Control . 3-6 3-2 Design Considerations 5-6 5-2

Commentary on Paragraph 3-2, Design

Basis 3-7 3-2

iEM 1110-2-2105

Change 1

31 May 94

Subject Paragraph Page

Commentary on Paragraph 5-3, Bolted

Connections 5-7 5-2

Commentary on Paragraph 5-4, Welded

Connections 5-8 5-2

Appendix A

References

Appendix B

Load and Resistance Factor Design

Criteria for Miter Gates

Appendix C

Tainter Gates

Appendix D

Tainter Valves

Appendix E

Bulkheads and Stoplogs

Appendix F

Vertical Lift Gates (Lock and Crest)

Appendix G

Hydroelectric and Pumping Plants

* Appendix H

Flood Closure Structures

Appendix I

Miscellaneous Hydraulic Steel Structures

Figure Page

B-1. Point load impact for miter

gate girders . B-3

B-2. Assumptions for intercostal

end connections B-5

B-3. Nomenclature and assumed load

area for intercostal design . B-6

B-4. Vertical cross section for

example miter gate B-8

B-5. Example miter gate loading B-9

Figure Page

B-6. Nomenclature for skin plate

design . B-11

B-7. Sample intercostal section . B-12

B-8. Girder hydrostatic loading and

reactions . B-14

B-9. Sample girder cross section B-14

B-10. Example miter leaf torsion loads . B-19

Engineering and Design

LUBRICANTS AND HYDRAULIC FLUIDS

Table of Contents

Subject Paragraph Page

Chapter 1

Introduction

Purpose . 1-1 1-1

Applicability 1-2 1-1

References . 1-3 1-1

Distribution Statement . 1-4 1-1

Scope 1-5 1-2

Chapter 2

Lubrication Principles

Friction 2-1 2-1

Wear . 2-2 2-4

Lubrication and Lubricants 2-3 2-6

Hydrodynamic or Fluid Film Lubrication 2-4 2-6

Boundary Lubrication 2-5 2-8

Extreme Pressure (EP) Lubrication 2-6 2-9

Elastohydrodynamic (EHD) Lubrication . 2-7 2-9

Chapter 3

Lubricating Oils

Oil Refining . 3-1 3-1

Types of Oil 3-2 3-2

Characteristics of Lubricating Oils . 3-3 3-4

Oil Classifications and Grading Systems 3-4 3-7

Chapter 4

Hydraulic Fluids

Purpose of Hydraulic Fluids . 4-1 4-1

Physical Characteristics . 4-2 4-1

Quality Requirements . 4-3 4-2

Use of Additives 4-4 4-4

Types of Hydraulic Fluids . 4-5 4-4

Cleanliness Requirements . 4-6 4-6

iEM 1110-2-1424

28 Feb 99

ii

Subject Paragraph Page

Chapter 5

Grease

Description . 5-1 5-1

Function . 5-2 5-1

Grease Characteristics . 5-3 5-2

Fluid Lubricants . 5-4 5-5

Soap Thickeners . 5-5 5-5

Complex Soap . 5-6 5-6

Additives . 5-7 5-6

Types of Greases . 5-8 5-6

Compatibility 5-9 5-8

Grease Application Guide . 5-10 5-8

Chapter 6

Nonfluid Lubrication

Solid Lubrication . 6-1 6-1

Self-Lubricating Bearings 6-2 6-6

Self-Lubricating Bearings for Olmsted Wicket Gates Prototype Tests 6-3 6-7

Chapter 7

Lubricant Additives

General 7-1 7-1

Surface Additives . 7-2 7-1

Performance-Enhancing Additives 7-3 7-3

Lubricant Protective Additives . 7-4 7-3

Precautions . 7-5 7-4

Chapter 8

Environmentally Acceptable Lubricants

General 8-1 8-1

Definition of Environmentally Acceptable (EA) Lubricants 8-2 8-1

Biodegradation . 8-3 8-2

Toxicity 8-4 8-3

EA Base Fluids and Additives . 8-5 8-3

Properties of Available EA Products 8-6 8-6

Environmentally Acceptable Guidelines 8-7 8-8

Changing from Conventional to EA Lubricants . 8-8 8-8

Survey of Corps Users . 8-9 8-9

USACE Contacts 8-10 8-10

Chapter 9

Gears

General 9-1 9-1

Gear Types . 9-2 9-1

Gear Wear and Failure . 9-3 9-2

Gear Lubrication . 9-4 9-6EM 1110-2-1424

28 Feb 99

iii

Subject Paragraph Page

Chapter 10

Bearings

General . 10-1 10-1

Plain Bearings 10-2 10-1

Rolling-Contact Bearings 10-3 10-6

Calculation of Bearing Lubrication Interval 10-4 10-12

Chapter 11

Lubrication Applications

Introduction 11-1 11-1

Turbines, Generators, Governors, and Transformers 11-2 11-1

Main Pumps and Motors 11-3 11-5

Gears, Gear Drives, and Speed Reducers 11-4 11-6

Couplings . 11-5 11-8

Hoists and Cranes . 11-6 11-9

Wire Rope Lubrication . 11-7 11-10

Chain Lubrication . 11-8 11-14

Trashrake Systems and Traveling Water Screens 11-9 11-17

Gates and Valves . 11-10 11-17

Navigation Lock Gates, Culvert Valves, and Dam Gates . 11-11 11-24

Information Sources for Lubricants . 11-12 11-26

Chapter 12

Operation and Maintenance Considerations

Introduction 12-1 12-1

Maintenance Schedules . 12-2 12-1

Relative Cost of Lubricants 12-3 12-1

Lubricating Oil Degradation 12-4 12-4

Hydraulic Oil Degradation . 12-5 12-5

Transformer and Circuit Breaker Insulating Oil Degradation . 12-6 12-6

Essential Properties of Oil . 12-7 12-7

Other Properties of Used Oils . 12-8 12-8

Oil Monitoring Program . 12-9 12-9

Oil Purification and Filtration . 12-10 12-14

Oil Operating Temperature . 12-11 12-21

Lubricant Storage and Handling 12-12 12-22

Safety and Health Hazards 12-13 12-28

Environmental Regulations 12-14 12-29

Chapter 13

Lubricant Specifications and Selection

Introduction 13-1 13-1

Lubricant Classification . 13-2 13-1

Principles of Selection 13-3 13-4

Specification Types 13-4 13-9

Lubricant Consolidation . 13-5 13-10EM 1110-2-1424

31 Jul 06

Change 1

iv

Appendix A

References

Appendix B

Survey of Locks and Dams for Lubricants

Appendix C

Specification for Turbine Oil

TABLE OF CONTENTS

1. GENERAL

2. REFERENCES

3. SUBMITTALS

4. TURBINE OIL CHARACTERISTICS AND REQUIREMENTS

5. COMPATIBILITY

6. PRE-DELIVERY TESTING

7. DELIVERY

8. INSPECTION AND ACCEPTANCE.

1. GENERAL

This specification covers zinc and chlorine-free rust and oxidation inhibited (R&O) mineral oils for

use in hydraulic turbine and generator bearings, Kaplan turbine hubs, hydraulic-turbine governors,

and other applications, where high-grade turbine oil having anti-corrosion, anti-oxidation, and

anti-foaming properties is required.

2. REFERENCES

The publications listed below form a part of this specification to the extent referenced. The

publications are referred to in the text by basic designation only.

AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM)

ASTM D 92 (2002b) Flash and Fire Points by Cleveland Open

Cup

ASTM D 97 (2004) Pour Point of Petroleum Oils

ASTM D 130 (2004) Corrosiveness to Copper from Petroleum

Products by Copper Strip Test

ASTM D 445 (2004e1) Kinematic Viscosity of Transparent and

Opaque Liquids (and the Calibration of Dynamic

Viscosity)

ASTM D 664 (2004e1) Acid Number of Petroleum Products by

Potentiometric Titration

ASTM D 665 (2003) Rust-Preventing Characteristics of Inhibited

Mineral Oil in the Presence of Water

C-3EM 1110-2-1424

26 Oct 07

Change 2

ASTM D 892 (2003) Foaming Characteristics of Lubricating Oils

ASTM D 943 (2004a) Oxidation Characteristics of Inhibited

Mineral Oils

ASTM D 1401 (2002) Water Separability of Petroleum Oils and

Synthetic Fluids

ASTM D 2270 (2004) Calculating Viscosity Index from Kinematic

Viscosity at 40 and 100 Degrees C

ASTM D 2272 (2002) Oxidation Stability of Steam Turbine Oils by

Rotating Pressure Vessel Oxidation Test

ASTM D 3427 (2003) Air Release Properties of Petroleum Oils

ASTM D 4057 (2000) Manual Sampling of Petroleum and

Petroleum ProductsASTM D 4177 (2000)

Automatic Sampling of Petroleum and Petroleum

Products)

ASTM D 6304 (2004ae1) Water in Petroleum Products, Lubricating

Oils, and Additives by Coulometric Karl Fisher

Titration

ASTM D 7155 (2006) Standard Practice for Evaluating

Compatibility of Mixtures of Turbine Lubricating

Oils

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION (ISO)

ISO 4406 (1999) Coding the Level of Contamination by Solid

Particles

ISO 11171 (1999) Calibration Of Automatic Particle Counters

TABLE OF CONTENTS

Section Page

Subcourse Overview i

Administrative Instructions .iii

Grading and Certification Instructions iv

Lesson 1: Hydraulic Pumps .11

Part A: PositiveDisplacement Pumps .12

Part B: Gear Pump .15

Part C: Vane Pump .111

Part D: Piston Pump .112

Practice Exercise .119

Answer Key and Feedback .122

Lesson 2: Hydraulic Valves 21

Part A: PressureControl Valves .22

Part B: DirectionalControl Valves .25

Part C ControlValve Repair .28

Practice Exercise .215

Answer Key and Feedback .218

Examination E1

Appendix A: List of Common Acronyms .A1

Appendix B: Recommended Reading List B1

Appendix C: Metric Conversion Chart .C1

iii EN 5260Appendix D: Publication Extracts .D1

Student Inquiry Sheets

Table of Contents

Subject Paragraph Page

CHAPTER 1. INTRODUCTION

Purpose 1-1 1-1

Applicability 1-2 1-1

References 1-3 1-1

Background 1-4 1-2

General Requirements 1-5 1-3

Scope 1-6 1-3

Computer Programs 1-7 1-3

Rescission 1-8 1-3

CHAPTER 2. DETAILS OF REINFORCEMENT

General 2-1 2-1

Quality 2-2 2-1

Anchorage, Bar Development, and Splices 2-3 2-1

Hooks and Bends 2-4 2-1

Bar Spacing 2-5 2-1

Concrete Protection for Reinforcement 2-6 2-2

Splicing 2-7 2-2

Temperature and Shrinkage Reinforcement 2-8 2-3

CHAPTER 3. STRENGTH AND SERVICEABILITY REQUIREMENTS

General 3-1 3-1

Stability Analysis 3-2 3-1

Required Strength 3-3 3-2

Design Strength of Reinforcement 3-4 3-6

Maximum Tension Reinforcement 3-5 3-6

Control of Deflections and Cracking 3-6 3-6

Minimum Thickness of Walls 3-7 3-

STRENGTH AND SERVICEABILITY COMMENTARY

General

Stability Analysis

Required Strength

CHAPTER 4. FLEXURAL AND AXIAL LOADS

Design Assumptions and General

Requirements

Flexural and Compressive

Capacity - Tension

Reinforcement Only

Flexural and Compressive

Capacity - Tension and Compression

Reinforcement

Flexural and Tensile Capacity

Biaxial Bending and Axial Load

CHAPTER 5. SHEAR

Shear Strength

Shear Strength for Special Straight

Members

Shear Strength for Curved Members

Empirical Approach

APPENDICES

Appendix A Notation A-1

Appendix B Derivation of Equations for

Flexural and Axial Loads

B-l

Appendix C Investigation Examples C-l

Appendix D Design Examples D-l

Appendix E Interaction Diagram E-l

Appendix F Axial Load with Biaxial Bending -

Example

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل كتاب The Basics of Hydraulic Systems

رابط مباشر لتنزيل كتاب The Basics of Hydraulic Systems

|

|

Dr.Mansour

مهندس تحت الاختبار

عدد المساهمات : 3

التقييم : 3

تاريخ التسجيل : 27/12/2019

العمر : 73

الدولة : Egypt

العمل : G.Manager

الجامعة : MTC

|  موضوع: رد: كتاب The Basics of Hydraulic Systems موضوع: رد: كتاب The Basics of Hydraulic Systems  الثلاثاء 31 مايو 2022, 5:40 pm الثلاثاء 31 مايو 2022, 5:40 pm | |

|

Thanks Dr. Eng. Mansour Soliman |

|