Admin

مدير المنتدى

عدد المساهمات : 18864

التقييم : 35108

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

|  موضوع: كتاب Composite Materials for Aircraft Structures موضوع: كتاب Composite Materials for Aircraft Structures  السبت 14 نوفمبر 2020, 10:37 am السبت 14 نوفمبر 2020, 10:37 am | |

|

أخوانى فى الله

أحضرت لكم كتاب

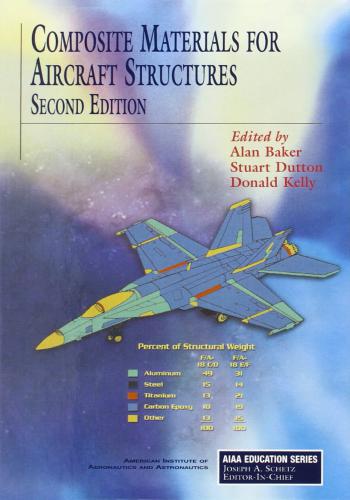

Composite Materials for Aircraft Structures

Second Edition

Alan Baker

Cooperative Research Centre for Advanced Composite Structures, and Defence

Science and Technology Organisation, Department of Defenee, Australia

Stuart Dutton

Cooperative Research Centre for Advanced Composite Structures

Donald Kelly

University of New South Wales

و المحتوى كما يلي :

Contents

Contributors

Chapter 1

Introduction and Overview

General

Drivers for Improved Airframe Materials

High-Performance Fiber Composite Concepts

Fiber Reinforcements

Matrices

Polymer Matrix Composites

Non-polymeric Composite Systems

Hybrid Metal/PMC Composites

References

Bibliography

Chapter 2

Basic Principles of Fiber Composite Materials

Introduction to Fiber Composite Systems

Micromechanical Versus Macromechanical

View of Composites

2.3 Micromechanics

2.4 Elastic Constants

2.5 Micromechanics Approach to Strength

2.6 Simple Estimate of Compressive Strength

2.7 Off-axis Strength in Tension

2.8 Fracture Toughness of Unidirectional Composites

References

Chapter 3 Fibers for Polymer-Matrix Composites

3.1 Overview

3.2 Glass Fibers

3.3 Carbon Fibers

3.4 Boron Fibers

3.5 Silicon Carbide

3.6 Aramid Fibers

3.7 Orientated Polyethylene Fibers

3.8 Dry Fiber Forms

References

79xiv CONTENTS

Chapter 4 Polymeric Matrix Materials

4.1 Introduction

4.2 Thermoset and Thermoplastic Polymer Matrix Materials

4.3 Thermosetting Resin Systems

4.4 Thermoplastic Systems

References

Chapter 5 Component Form and Manufacture

5.1 Introduction

5.2 Outline of General Laminating Procedures

5.3 Laminating Procedures For Aircraft-Grade Composite

Components

5.4 Liquid Resin Molding Techniques

5.5 Filament Winding

5.6 Pultrusion

5.7 Process Modelling

5.8 Tooling

5.9 Special Thermoplastic Techniques

References

Chapter 6 Structural Analysis

6.1 Overview

6.2 Laminate Theory

6.3 Stress Concentration and Edge Effects

6.4 Failure Theories

6.5 Fracture Mechanics

6.6 Failure Prediction Near Stress Raisers and Damage Tolerance

6.7 Buckling

6.8 Summary

References

Chapter 7 Mechanical Property Measurement

7.1 Introduction

7.2 Coupon Tests

7.3 Laboratory Simulation of Environmental Effects

7.4 Measurement of Residual Strength

7.5 Measurement of Interlaminar Fracture Energy

References

Chapter 8 Properties of Composite Systems

8.1 Introduction

8.2 Glass-Fiber Composite Systems

8.3 Boron Fiber Composite Systems

8.4 Aramid Fiber Composite Systems

8.5 Carbon Fiber Systems

8.6 Properties of Laminates

262CONTENTS xv

Impact Damage Resistance

Fatigue of Composite Laminates

Environmental Effects

References

Chapter 9

Joining of Composite Structures

Introduction

Comparison Between Mechanically Fastened and

Adhesively Bonded Joints

Adhesively Bonded Joints

Mechanically Fastened Joints

References

Chapter 10

Repair Technology

Introduction

Assessment of the Need to Repair

Classification of Types of Structure

Repair Requirements

Non-patch Repairs

Patch Repairs: General Considerations

Bonded Patch Repairs

Materials Engineering Aspects

Application Technology: In Situ Repairs

Bolted Repairs

Materials Engineering Aspects

References

Chapter 11 Quality Assurance

11.1 Introduction

11.2 Quality Control

11.3 Cure Monitoring

11.4 Non-destructive Inspection of Advanced Composite

Aerospace Structures

11.5 Conclusion

References

Chapter 12

Aircraft Applications and Design Issues

Overview

Applications of Glass-Fiber Composites

Current Applications

Design Considerations

Design of Carbon-Fiber-Based Components

Design Methodologies

462xvi CONTENTS

12.7 A Value Engineering Approach to the Use of

Composite Materials

12.8 Conclusion

References

Chapter 13 Airworthiness Considerations For Airframe

Structures

13.1 Overview

13.2 Certification of Airframe Structures

13.3 The Development of Design Allowables

13.4 Demonstration of Static Strength

13.5 Demonstration of Fatigue Strength

13.6 Demonstration of Damage Tolerance

13.7 Assessment of the Impact Damage Threat

References

Chapter 14 Three-Dimensionally Reinforced Preforms and

Composites

14.1 Introduction

14.2 Stitching

14.3 Z-Pinning

14.4 Three-Dimensional Weaving

14.5 Braiding

14.6 Knitting

14.7 Non-crimp Fabrics

14.8 Conclusion

References

Chapter 15 Smart Structures

Chapter 16

Introduction

Engineering Approaches

Selected Applications and Demonstrators

Key Technology Needs

References

Knowledge-Based Engineering, Computer-Aided

Design, and Finite Element Analysis

16.1 Knowledge-Based Design Systems

16.2 Finite Element Modelling of Composite Structures

16.3 Finite Element Solution Process

16.4 Element Types

16.5 Finite Element Modelling of Composite Structures

16.6 Implementation

16.7 Design Optimization

References

569CONTENTS

Appendix Overview of Some Sensors and Actuators Used for

Smart Structure Applications

A.1 Piezoelectric Materials

A.2 Shape Memory Alloys

A.3 Optical Fiber Sensors

A.4 Electrorheological Fluids

A.5 Magnetostrictive Materials

A.6 Micro-Electro-Mechanical Systems

A.7 Comparison Of Actuators

References

Index

Index

Accelerated testing, 226

Acoustic emission, 429

Acoustic excitation, 427

Acoustic impact, 430

Acoustic sensing, 417, 427

Acousto-ultrasonics, 429-30, 537

Active fiber composite system, 572

Actuators, 525, 527

smart structure applications, 578-9

Addition polymerization, 83

Adhesive spew, 312-13

Adhesive strength, strength analysis based

on, 382-3

Adhesively bonded joints, 63, 290-1,297

adhesive stress/strain behavior models,

298

advantages and disadvantages, 291

classification and applications, 293

complications, 297-8

configuration and analysis of single-lap

joint, 301

design/analysis of bonded lap joints,

296-8

design input parameters, 293

double-overlap joint, 305-13

overlap-length, balanced joint, 308

effects of defects in lap joints, 313-14

failure modes, 292-3

fatigue, 328-32

load-carrying, 294

load-transfer mechanisms in overlap

joints, 300-5

materials aspects, 319-23

moisture effects on, 332-6

overview, 292-5

properties required, 293-4

scarf joints, 317-19

model for analysis, 320

shear stress/length and shear strain/

length distribution in skin-doubler

joint, 303

skin-doubler joint

analysis, 302

with stepped ends, 305-6

step-lap joint, 314--17

manufacturing process, 317

stress analysis programs, 297

581

surface treatment, 336

types of joint, 295

Adhesives:

B-staged, 391

C-staged, 391

elastic model, 300-3

elastic/plastic model, 303-5

endurance testing, 329

film, 329

forms available, 321-2

fracture behavior, 326

fracture energy, 325-8

paste, 321,391

properties, 328

repair, 390-2

selection, 322-3

shear stress distribution in, 308

shear stress/length distribution in, 307

stress/strain properties, 298, 323-5

structural, 319-21

temperature effects, 331-2

Airborne Early Warning and Control

(AEW&C) military aircraft, 436

Airbus A300, fin box, 161

Airbus A380, 437

Aircraft applications, 435-47

cobonded blade stiffener, 446

common configurations, 443-7

fiber composite forms, 114

fixed wing civil aircraft, 436-8

fixed wing military aircraft, 438-42

integrally cured blade stiffener, 446

secondary bonded blade stiffener, 446

Aircraft wing covers, 497

Airframe materials:

drivers for improved, 3

properties assumed for, 468

weight ratios for, 471

Airframe structures, 1

certification, 480-2

certification tests, 481

growth in use of advanced composites, 2

Airworthiness, 477-89

certification requirements, 479

regulations, 477

use of term, 477

Aligned fiber sheets, 113582 INDEX

Aluminum2024 T3, 239-40

tension-tension fatigue results, 252

Aluminum7075 T6, 276

Aluminumalloy, 1, 11,440

crack growth in, 329

patches, 399

strength of, 451

tooling, 158-9

Aluminum/fiber composite hybrid laminate, 19

Aluminummatrix MMCs, 15

American Society for Testing and

Materials (ASTM), 214, 218, 221-3,

234, 404-5

Amorphous structure, 83

Amorphous thermoplastic, 84

Angle-minus-loaded (AML) ply curve, 459

Anhydride-cured bisphenol A epoxies, 251

Antimony oxide, 98

ARALL, 19-20

Aramid/epoxy pre-preg laminates, 251

Aramid fiber composite systems, 249-57

applications, 250

costs, 241

cutting, drilling and machining, 251

fatigue resistance, 252

impact and ballistic properties, 254-5

manufacturing issues, 251

matrix systems, 251

mechanical properties, 251-3

pressure vessels and containment rings, 256

tensile and compression stress-strain

curves, 250

unidirection properties, 240

vibration damping, 255

Aramid fibers, 71

applications, 71

creep rate, 252-3

energy absorption during fracture,71

environmental effects, 253

failure by defibrillation process, 73

moisture absorption, 73

plastic behavior, 71

polymeric structure, 72

short-term creep, 73

stress rupture, 252-3

ultraviolet radiation, 73

Aramid/hybrid composites:

open-hole tensile strength, 257

properties of, 256-7

Aromatic rings, 83

Arrhenius-type equation, 152

Aspect ratio, 23

Autoclave, 126

Autoclave cycle, 127

Autoclave molds, 128

processing problems, 128-30

Automated tape layers (ATL), 123

Automated tow placement (ATP), 123

AV8B aircrai~,441

Average stress criterion, 206, 340

Bagging process, 116, 124-5

Ballistic properties, aramid fiber composites,

254-5

Barely visibleimpact damage (BVID), 229,

264, 273, 370-I, 455-8

fatigue strength, 274

fatigue studies, 371

residual strength, 265--6

Bearing/bypass experiments for tension or

compression loading, 354

Bearing/bypass interaction under tensile

loading, 354

Bearing failure in mechanically fastened

joints, 344-5

Bearing strength:

function of temperature, 347

vs. clamp-up pressure, 345

BeechcraR Starship, 438, 506

Bending:

of orthotropic plate, 190

of simply-supported beam, 189

of symmetric laminates, 188-90

Bending load, 186-90

Bending stiffness, 190

Benzoyl peroxide (BzP), 100

Bird strikes, 458

Bismaleimide resins (BMIs), 9, 87,

103-5

4,4-Bismaleimidodiphenylmethane,104

Bisphenol A-epichorohydrin (DGEBA)

resins, 92, 94

Block copolymer, 82

Boeing B777, 437

Bolted joints, 290

advantages and disadvantages, 291

combined with adhesively bonded

joints, 365

optimization of load sharing, 357

ply configuration in, 339--40

see also Mechanically fastenedjoints

Bolted repairs, 395-8

laminates, 399

Bonded joints, 362, 450

damage growth for, 484

Boron/aluminumcomposite, 14-15

Boron fiber composite systems, 247-9

aircrafi application, 248-9

costs, 241

handling and processing properties, 248

mechanical properties, 248

overview, 247-8

repair material for defective metallic

structures, 249

unidirectional properties, 240INDEX 583

Boron fibers, 67-9, 448

anelastic deformation, 69

coating, 69

forms available, 248

manufacture, 68

properties of, 68

Borsic, 69

Boundary layer, 184-5

Braiding, 78, 113-14, 448, 507-15

applications, 512

design of composites, 511

four-step (or row-and-column), 513

manufacturing issues, 510-11

mechanical properties, 511- 12

multi-layer interlock, 513

patterns produced by, 510

research and development, 509-10

three-dimensional

applications, 515

architecture, 513

in-plane properties, 514

mechanical properties, 514-15

out-of-plane properties, 515

process, 512-14

two-dimensional process, 508-10

two-step, 513

Braiding machine, 508-9

Branched polymers, 82

Brick elements, 564-5

B-staged epoxy pre-preg, 117-18

Buckling:

fibers, 208

laminates, 190, 207-8

specimen, 218

Buckling modes, 44

extensional mode, 42-5

shear mode, 42-5

unidirectional composite, 45

CAD/CAM, 510

Carbon/aluminum alloy composites, 14

Carbon/carbon composites, 13, 18-19

Carbon-epoxy composites, 11

allowable design range, 462

AS4/3501-6, 276

curing, 126

impact energy for, 264

patch repairs, 398

Carbon-epoxy laminates:

impact damage, 455

off-axis, 176

polyimide coated fiber in, 533

strength of, 451

Carbon fiber-based components, design

considerations, 449-62

Carbon fiber composite systems, 257-61

applications, 257

compression, 260-1

deformation, 261

effect of matrix and fiber/matrix bond

strength, 260-1

intra and interlaminar properties, 261

matrix systems, 258

mechanical properties, 257, 259

PAN-based, 257-8

tension, 260-1

unidirectional properties, 240

Carbon fiber/epoxy composites, 1

fatigue-life diagram, 269

rib, 122

tension-tension cycling, 268

Carbon fiber reinforced plastic (CFRP), 13

Carbon fiber reinforcements, 258

Carbon fiber tows, 149

Carbon fibers, 6, 14, 448

adhesion, 260

bonding, 260

high modulus (HM, Type I), 63-4

high strength (HS, Type II), 63-4

manufacture, 63-4

PAN-based, 64-6

pitch-based, 66-7

properties of major types, 64

strength and stiffness, 65

strength distribution, 39

structure, 67

surface treatments, 260

Carbon/magnesium alloy composites, 14

Carbon matrices, 12

Carbon nanotubes, 6

Carbonization process, 64-5

Carboxy-terminated butadiene nitrile

rubber (CTBN), 96

CATIA V5 software, 550

Ceramic fibers, 56

Ceramic materials, piezoelectric, 571-2

Ceramic matrix composites (CMCs),

11-13, 17-19

Chain configurations, 81

Characteristic damage state (CDS), 270

Chemical vapor deposition (CVD), 6,

12-14, 68-9

Coatings, glass fibers, 62-3

Cocuring:

carbon/epoxy wing structure, 129

complex components, 128

concept of, 161

Coefficient of thermal expansion (CTE), 127,

131, 158-9

see also Longitudinal expansion

constants; Transverse expansion

coefficient

Combined countersinking, 132

Combined loading and environmental

conditioning, 226584 INDEX

Commercial Modelling Systems, 551

Compliance calibration (CC) method,

233-4

Component form and manufacture, 113-69

Composite honeycomb, 115

Composite systems:

properties of, 239-87

unidirectional properties of, 240

Composites and metals, critical difference

between, 478

Compression:

carbon-fiber composites, 260-1

coupon tests, 217-20

Compression after impact (CAI) strength, 229

for stitched and unstitched laminates, 495

Compression fatigue, 273

Compression molding, 116, 167

Compression residual strength for XAS/914C

laminate, 275

Compression strength:

and damage diameter, 228

simple estimate, 42-5

temperature effect on, 461

Compression testing:

failure modes in, 220

fixture for, 231

open-hole, 218

Compressive matrix failure, 197

Computer-aided engineering (CAE), 549,

568-9

Computer modelling, 131

Condensation polyimides, 105

Condensation polymerization, 83

Consolidation model, 155-6

Contiguity concept used for semi-empiricalelasticity solutions, 35

Continuous matrix, 113

Control surface, "hinged" and "hingeless", 543

Copolymer, 82

Core-crashing, 130

Corrosion prevention, 364

Cost estimates for design optimization, 568-9

Cost issues, 1, 3

Cost/performance trade-offs, 467-9

Cost value analysis of weight-saving,

469-74

Costs of high-temperature thermoplastic

materials, 447

Countersinking, 361

Coupling agents, 63

Coupon tests, 482

design of program, 227-30

tension, 216-17

variabilities encountered in, 215

Crack bridging, 51

Crack growth:

aluminum alloys, 329

direction of, 52

Crack opening modes, 204, 232

Crack propagation, 52

energetic requirement for, 49

mode II, 330

under loading, 329

unidirectional composites, 48-9

Crack turning or splitting, 52

Cracked-lap shear (CLS) specimen, 236

Creep rate, aramid fibers, 252-3

Critical transfer length, 38

Cross-linked polymers, 82

Cross-ply composites, tension fatigue, 270-1

Cross-ply laminates, tensile strength, 262-3

Cross-sectional laminates, 533

Crystalline regions, 83-4

Crystalline thermoplastic, 84

Cumulative damage, Rosen model of, 39-42

Cure monitoring, 408-13

acoustic methods, 411

displacement transducers, 412-13

electrical measurements, 409-10

optical methods, 412

pressure and compaction sensors, 412-13

sensor placement, 408-9

techniques and their performance, 413

thermal properties, 412

Curing process, 83, 125-8

modelling, 152-3

polyester resins, 99-100

see also Cocuring

Cutting room, 119-20

Cyanate ester, cross-linked, 107

Cyanate ester monomer, 107

Cyanate resins, 106-7

curing chemistry, 106

properties, 106-7

Cyclic loading, 484

tests, 213

Cyclic phosphine oxide, 98

Damage detection/monitoring, 528,

533-4, 536-7

see also Impact damage

Damage diameter and compression

strength, 228

Damage effects on design allowables,484

Damage growth, 275-6

bonded joints, 484

due to fatigue, 478, 483-4

prediction, 458

Damage in service:

major types, 370

sources of, 369

Damage mitigation, 540-3

Damage tolerance, 204-7, 478-9

demonstration of, 487

effect of stitching, 494INDEX 585

general requirement, 480

improvements, 458-60

laminates, 207, 457

Darcy's law, 140, 153--4

DASH-8 aircrat~, 534

Debagging, 131

Defects during manufacture and service, 228

Defense Advanced Research Projects

Agency (DARPA), 541

Deformation, carbon-fiber composites, 261

Degree of contiguity, 33

Degree of crystallinity, 83-4

Delamination, 185, 194, 232, 264, 275

fracture toughness, 460

injection repairs, 375-7

sources, 452

suppression of, 495-6

Delamination growth, 195

Delamination pattern, 265

Delta wing unmanned aerial vehicles, 543

Design allowables, 227

aircraft structures, 482-4

influence of damage, 484

Design considerations, 447-53

carbon-fiber-based components, 449-62

choice of materials, 447-8

general guidelines, 448-9

Design methodologies, 462-6

Design optimization, 568-9

cost estimates for, 568-9

Design process:

automation, 551,568

outline, 464

Design systems:

knowledge-based, 549-51

structural component, 551

Destructive tests, 407-8

DGEBA, 92, 94

Diaminodiphenylmethane precursor, 104

Diaphragm forming:

in autoclave, 166

in mold, 166

process, 122

thermoplastic composites, 165-6

Dielectric loss factor and cure temperature

vs. time, 410

Dielectrometry, 409-10

Diffusion bonding, 11

Diffusion coefficient, 333

Diffusion constant, 279

Diffusion of moisture s e e Moisture diffusion

Diluents, 94

Disbond growth under cyclic loading

conditions, 330

Disbond propagation, 329

Distortion, 130

process-induced, 156-7

Double-cantilever-beam (DCB) specimens,

233

Drape test, 405

Drill-bit configuration, 132

Drilling, 131-2

Durability allowables, 483

Durability/economic requirement, 480-1

Edge crack torsion test (ECT), mode III, 237

Edge effects, 192-4

Edge-notched flexural specimen, 331

Effective stress concetration factor, 342

E-glass composites, costs, 242

E-glass fibers, 241,435

stress rupture strength of, 246

E-glass laminates, 435

E-glass/vinyl ester knitted composites, 518

E-glass/vinyl ester three-dimensional

orthogonal weave, 504

Elastic constants:

direct approaches, 33

energy approach, 32-3

mechanics of materials approach, 26-31

theory of elasticity approach, 32-5

Elastic modulus, silicon carbide, 70

Electrical conduction, measurement of, 410-11

Electro-discharge machining (EDM), 578

Electromagnetic acoustic transducers (EMAT),

424

Electrorheological fluids, 577

Embroidery, 498

producing local, optimized reinforcement,

498

End-loaded split (ELS) specimen, 235-6

End-notched flexure (ENF) specimen, 235-6

Energy release rate, 52

Engineering Sciences Data Unit (ESDU), 297

ENSTAFF, 226

Environmental effects, 460, 478-9, 484-5, 533

aramid fibers, 253

glass-fiber composites, 246-7

laboratory simulation, 225-6

mechanical properties, 276-86

Epoxy-nitrile film adhesives, 328

Epoxy resins, 87-98, 258

additives, 94

advantages and disadvantages, 98

anomalies in behavior, 97

curing, 92-4

flame retardants, 97-8

formulating with, 94

fracture energy, 96

moisture sensitivity, 96-7

properties, 9

pultmsion, 147586 INDEX

structural I-beam, 149

thermal resistance, 97-8

toughening, 95

use in aerospace composite matrices, 92

Expansion constants ctUlu and ctU2u, 33-5

Experimental validation, process modelling,

157

Extended airframe life, 530-1

Extensional bending stiffness matrix, 188

Extensional modulus off-axis laminate, 176

F-15 aircraft, 543

F-18 E/F aircraft, 1-2, 440

F-22 aircratL 440

F-35 aircraft, 506

FAA AC 20-107A document, 479

Fabrics:

orientations, 151

tensile testing, 404

see also Weaving

Failure, in laminates, 194

Failure categories, weight ratio equations

for, 470

Failure criterion, 195--6

Failure loci in composites, 326

Failure modes, 86, 325-6

adhesively bonded joints, 292-3

compression testing, 220

cyclic loading, 331-2

mechanically fastened joints, 338

tensile testing, 217

weight-saving as function of, 467-9

Failure prediction:

comparison of models, 202-3

near stress raisers, 204-7

Failure strain, lay-up effect on, 459

Failure stresses for circular holes,

comparison of predicted and

experimental, 206

Failure theories, 194-203

stress-based, 195-9

Fasteners:

for composites, 361-2

metallic, 362

non-metallic, 362

Fatigue:

adhesively bonded joints, 328-32

damage growth due to, 478, 483-4

Fatigue cycling, 230

Fatigue damage:

changes in stiffness and residual

strength due to, 272

laminates, 271

Fatigue design allowables, 483-4

Fatigue life, 487

Fatigue-life curves for tension-tension

loading, 244

Fatigue-life diagrams, 268-70

Fatigue loading, 230-1

fi'cquency effect, 272-3

mechanically fastened joints

loaded holes, 360

open holes, 359-60

thermography, 232

Fatigue performance, 224-5

glass/epoxy composites, 243-4

glass-fiber systems, 243-5

stitched composites, 496

Fatigue resistance:

aramid composites, 252

laminates, 266-76

testing, 267

Fatigue strength:

alternate load path, 480

and BVID, 274

demonstration of, 486-7

fail-safe approaches, 480

safe life approach, 480

slow crack growth approach, 480

Fatigue studies, BVID, 371

Fatigue tests, 477, 483

full-scale, 486

Fiber architecture, z-direction, 491

Fiber Bragg grating sensor, 534-5, 575-6

Fiber buckling, 208

Fiber bundles, chain of, 40, 43

Fiber composites:

basic principles, 23-54

classification, 24

constituents, 23

forms, structure and application, 75-6, 114

macromechanics, 23

micromechanics, 23-6

typical models for exact elasticity solutions,

34

Fiber crimping, 7

Fiber-dominated properties, 461

Fiber debonding, 49, 51

Fiber directions, tailoring, 5

Fiber fractures:

ineffective length at break, 41

perturbation of stress in adjacent fiber, 41

vs. fraction of ultimate composite strength,

40

Fiber/matrix bond strength, 38

Fiber/matrix debonding, 38

Fiber/matrix interaction, 38

Fiber/matrix interface, 4, 49

Fiber/matrix stiffness ratio, 267

Fiber orientation, 5, 113, 182

Fiber reinforcement, 6-7, 113

resin flow through, 153-5

Fiber stress, 44

Fiber types:

maximum operating temperature, 58-9INDEX 587

mechanical properties, 58-9

vs. specific strength, 56-7

Fiber volume fraction, 36, 56-7, 155-6

Fiber waviness, 144

Fibers:

compressive failure, 197

dry forms, 74-9

flaws in, 55, 61

manufacturing processes, 55

microbuckling of, 218

polymer, 56

for polymer-matrix composites, 55-80

testing, 403-4

see also specific fiber types

Fickian/non-Fickian diffusion, 278, 333

Fick's first law of diffusion, 278

Fick's second law of diffusion, 278

Fictive temperature, 60

Fighter aircraft:

structural breakdown, 469

value indices for, 473

Filament winding, 113-14, 140-5

applications, 144-5

basic machine, 141-2

design and properties of structures, 144

design of mandrels, 142

materials, 142-4

overview, 140

thermoplastics, 143-4, 164

thermosets, 143

winding patterns, 142, 144

Filled-hole tension (FHT), 459

Filler repairs, 374

Fillers, inert, 95

Film adhesives, 321-2

for repair work, 391

Finishes, 63

Finishing, 131

Finite element analysis (FEA), 184, 330,

453, 549, 552

1-D example, 554

element types, 562-3

element types in element library, 561

Finite element modelling (FEM), 171,

481,552-3

basic steps, 554-62

composite structures, 563-6

implementation, 566-7

plate and shell elements, 564-6

wing spoiler, 553

Finite element solution process, 553-62

First invariant strain criterion for matrix

failure, 201

First ply failure (FPF), 194-5, 262, 270

Flammability, 479

Flat panel molding, 167

Flaws in fibers, 55, 61

Flexibilizers, 95

Flexible mandrels, 161

Flexure tests, 220-2

four-point bending, 221

three-point bending, 221

Flow control, 541-2

Forming:

mapping or kimematic approach, 150-1

mechanics approach, 151

process, 113

process modelling, 150-1

Fourier transform infrared spectra (FTIR), 97

Fracture behavior:

brittle fiber/brittle matrix composite, 50

brittle fiber/ductile matrix composite, 50

Fracture energy:

adhesives, 325-8

joint strength estimation based on, 327-8

Fracture energy/area method, 234-5

Fracture mechanics, 49-52, 195, 203-4

design of joints, 327

Fracture mechanics-type lap joint tests, 329

Fracture surface energy, 47-9

Fracture toughness:

Mode I, 518

unidirectional composites, 47-52

Full-scale tests, 230-1,485-6

Fusion repairs for thermoplastics, 376

Gating, 135

Gause Error Function, 334

GLARE, 19-20

Glass-ceramic matrices, 12

Glass/epoxy composites:

fatigue performance, 243

fatigue performance of, 244

Glass fiber composites, 435--6

costs, 241

environmental effects, 246-7

fatigue performance, 243-5

impact strength, 245

mechanical properties, 241-7

stress effects, 246

tensile strength, 243

unidirectional properties, 240

Young's modulus, 242

Glass fibers:

chemical composition, 62

coatings, 62-3

effect of flaws, 61

E-glass, 62

manufacture, 57-61

S-glass, 62

types, 61-2

Glass matrices, 12

Glass/polyester systems:

EUlu versus VUfu,29

EU2u versus VUfu,30588 INDEX

Glass transition temperature, 84-5, 194, 460

Glassy state, 94

Graft copolymer, 82

Graphite, 63

Graphitisation, 66

Griffith equation, 51

Gurney and Hunt critical strain energy

release state, 233

Hardwood, 160

Harrier aircraft, 440

Hashin-Rotem failure criterion, 197

Health and usage monitoring system

(HUMS), 528-9

Heat transfer, process modelling, 152-3

Heating/pressure cycles, 127

Helical winding, 142

Helicopters, 443

High modulus polyethylene fibers, 73

High-performancefiber composite concepts, 3-6

Hi-Nicalon, 71

Hole preparation, 362-3

Hole-strengthening procedures, 363-4

Holography, 417, 427

Homopolymer, 82

Honeycomb construction, 115, 445

Honeycomb core, 130

Honeycomb panel, 445

moisture problems, 394

scarf repairs, 385

Honeycomb sandwich structures, 445, 506

Honeycomb structures:

external patch repairs, 381

repair, 369, 375

Hot-melt film pre-pregging process, 118

Hot-pressing, 11, 87

Humidity and moisture uptake, 280

Hy-Bor, 248

Hybrid metal/PMC composites, 19-20

Hydrogen bonding, 72

Hydroxyl group reaction, 93

Illinois Institute of Technology Research

Institute (IITRI) method, 218

Impact damage, 453-7

assessment of threat, 487-8

assumptions, 456

carbon/epoxy laminates, 455

categories, 454-6

effect of stitching, 494

and residual strength, 457

resistance, 263-4

strength loss associated with, 457

XAS/914C laminate, 265

Impact energy:

carbon/epoxy composites, 264

dropped tools, 454

vs. residual compression strength, 266

Impact energy absorption of composite and

non-composite materials, 246

Impact properties, aramid fiber composites,

254-5

Impact strength of glass-fiber systems, 245

Improved operations, 528-31

In-plane elastic properties, 215

In-plane shear modulus, 23, 31

In-plane stiffness matrix, 179

Inspection, 407-8

Intellectual property (IP), 551

Interracial strength degradation due to

moisture absorption, 335--6

Interlaminar failure, 199

Interlaminar fracture energy, measurement

of, 231-7

Interlaminar fracture resistance, 232

Interlaminar fracture test:

mixed mode, 236

mode I, 233

mode II, 235-6

mode IIl, 237

Interlaminar fracture toughness, area

method, 235

Interlaminar shear failure, 198

Interlaminar shear stress, 194, 260

Interlaminar strength, 199

Interlaminar tension, 198

Intermediate forms, 162-3

Interphase, 7

Invar tooling, 159

Iosipescu test, 222

Iron-based matrix, 16

Joining of composite structures, 289-368

adhesively bonded joints, 292-336

design parameters, 290

joint types, 289

multiple load path joints, 290

overview, 289-90

quality control, 290

single load path joints, 289-90

techniques, 1

see also Adhesively bonded joints;

Bolted joints; Mechanically

fastened joints; Riveted joints

Joint Airworthiness Authority (JAA), 456

Joint Airworthiness Committee, 477

Joint Strike Fighter aircrafi, 440, 442

KBE tools, 569

Kevlar fibers, 71-2, 255, 448

physical and mechanical properties, 71

see also Aramid fiberINDEX 589

Kevlar-49, 254

moisture absorption, 73

Kevlar-49/epoxy, tension-tension fatigue

results, 252

Kevlar-49/epoxy composites, 249

Kevlar-149, moisture absorption, 73

Kink band formation, 218

Knitting, 515-19

applications, 518-19

in-plane properties, 517-18

mechanical properties, 517-18

out-of-plane properties, 518

structural modelling, 564

weft and warp, 516

Knitting machines, 517

Knockdown factor, 229, 231,464-6

compression residual strength, 465

for tension- and compression-dominated

fatigue spectrum loading, 466

Knowledge-based design systems, 549-51

Knowledge-based engineering (KBE),

549-69

application, 550

Kozeny-Carman equation, 156

Kozeny constant, 156

Ladder polymers, 82

Lamina, 171

failure criterion, 198

Laminate axes, 171

for single ply, 174

Laminate codes, 185~5

Laminate stiffness matrix, 177-9

Laminate strength, 215

Laminate thickness, 177, 184

Laminated plates, buckling of, 190

Laminates, 52, 114

bolted repair, 399

buckling, 190, 207-8

compression after impact (CAI) strength

for stitched and unstitched, 495

cross-plied, 262

damage tolerance, 207, 457

failure in, 194

fatigue damage, 271

fatigue resistance, 266-76

loaded hole strength, 343

mois~tre problems, 393-4

oahotropic in bending, 188-9

orthotropic ply material for, 564

performance of, 450

properties of, 262-3

quasi-isotropic, 183, 496

SIFT applied to, 202

stitched, 495

stress-based failure theories, 198-9

stress concentration factors, 450

stress-strain law for, 179

subjected to plane stress and bending

loads, 186--90

symmetric and non-symmetric eight-ply, 177

tests, 405

with unloaded holes, stress concetrations

in, 340-5

Laminating:

procedures, 115-32

woven cloth, 113

Laminiates:

theory, 172-90

assumptions, 172

Laser beam ultrasound, 424

Laser cutting, 120-1

Lay-up, 171, 181,450

automated, 122-4

effect on failure strain, 459

process, 121

under vacuum, 126

Lead zirconate titanate (PZT), 571

Life extension, 528

Lightning effects, 461-2

Linear elastic fracture mechanics (LEFM),

265

Linear molecules, 82

Linear polymers, 82, 84-5

Liquid molding, 113

Load measurement, 216

Load monitoring, 533-4

Load transfer behavior, metals vs.

composites, 353

Loaded hole strength of laminates, 343

Lockheed Martin air inlet duct, 506

Longitudinal expansion coefficient, 34

Longitudinal modulus, 23, 26, 32

LSDYNA, 266

Magnetostrictive materials, 577

Major Poisson's ratio, 23, 31

Mandrels, 161-2

Manufacturing defects, 453

Matched-die molding, 116-17

Material axes for single ply, 172

Material behavior, linear and non-linear, 559

Material control, 406-7

Matrix, 7-13, 81

ceramics, 11-13, 17-19

chemical changes, 286

cracking, 194

economic production, 8

functions, 81

manufacture, 9

metals, 10-11, 13-16

polymers, 8-10, 81

softening, 460

toughness, 8590 INDEX

Matrix-dominated properties, 81

Matrix equation, 556

Matrix failure envelopes, 202

Matrix materials, 81-112

overview, 87-8

properties of, 91

thermoplastics, 86-8

thermosets, 86-8

see also specific materials

Matrix plastic deformation, 49, 51

Mats, 77

Maximum strain failure envelope, 200

Maximum stress theory, 195

MD Explorer, 444

Mechanical properties:

environmental effects, 276-86

measurement, 213-38

moisture effect, 282-4

temperature effect, 282-4

see also specific materials

Mechanical testing:

machines for, 214

objectives, 213

special requirements for composites, 214-15

standardization, 214

types, 213-14

Mechanically fastened joints, 290-1,337-65

allowable strain and joint efficiency for

multi-row and single fastener

composite joints under tensile loading,

356

allowable stresses, 339

beating failure in, 344-5

combined with adhesively bonded joints,

365

component alignment, 364-5

design considerations, 337-40

design criteria for failure of single-hole

joints under static tensile loads, 340-6

double-lap bolted joint used to obtain test

data, 341

double-shear joints, 360-1

failure modes, 338

general materials engineering aspects, 361-5

loaded holes, fatigue loading for, 360

multi-row joints, 349-59

open holes, fatigue loading for, 359-60

shear-out failure, 345-6

single fastener joint loading efficiency

in compression, 348-9

in tension, 347-8

single-shear joints, 360-1

tension failure in, 342

see also Bolted joints; Joining of composite

structures

Medium-density fiberboard (MDF), 160

Mesophase (MP) based fibers, 66-7

Metal dies, 168

Metal mandrels, 162

Metal-matrix composites (MMCs), 10-11,

13-16

Metallic honeycomb, 115

Metals and composites, critical difference

between, 478

Methylethyl ketone peroxide (MEKP), 100

Micro-buckling of fibers, 208, 218

Micro-cracking, 262

Micro-electro-mechanical systems (MEMS),

527, 577-8

shear stress sensors, 543

technology, 543-4

Micro-electro-opto-mechanical systems

(MEOMS), 527

Micro-Fiber Composite system, 572

Micromechanics:

approach to strength, 36--42

finite-element (F-E) approach, 25

mechanics of materials approach, 25

theory of elasticity approach, 25

Micro-sloughing, 147

MIL-HDBK 17, 214-15, 223, 226, 284

Modified beam theory (MBT) method, 234

Modified compliance calibration (MCC)

method, 234

Moisture absorption, 277-80, 332-6, 478-9

and relative humidity, 280

Moisture concentration gradient, 278

Moisture conditioning, 225-6

Moisture diffusion, 277-8, 280, 333-5

Moisture effects:

on adhesively bonded joints, 332-6

on mechanical properties, 282-4

Moisture exposure, 460-1

Moisture flux, 278

Moisture problems, 393-4

honeycomb panel, 394

laminates, 393-4

Moisture uptake:

and humidity, 280

concentration, 279

vs. root time, 278

Molecular chains, 83

Molecular configuration, 82

Molecular weight, 85

Multi-functional structures, 543-4

Multi-layered fabrics, 519

Multi-row joints, 349-59

optimum design, 357-9

Network formation, 83

Nicalon:

applications, 71

creep resistance, 71

properties, 70

resistivity, 71INDEX 591

Nickel, electroplated or electroformed

tooling, 159

Nickel-titanium alloy, 573

Non-crimp fabrics, 78-9, 519-23

Non-destructive inspection (NDI), 290, 374,

392, 407, 414-30, 486

common defects found, 415

current technologies, 418

emerging technologies, 422-30

miscellaneous techniques, 416-17

optical methods, 427

requirements for quality assurance, 414

see also specific techniques

Non-polymeric composite systems, 13-19

Non-woven fabrics, 77

Notch-sensitive and notch-insensitive

behavior, 53

Notched/unnotched strength ratio, 206

Nuclear magnetic resonance (NMR), 97

Nylon, 72

Occupational health and safety (OH&S)

concems, 115

Off-axis laminates, 174-6

Off-Axis tensile shear test, 223

Off-axis tension, 45-7

resolution of forces and areas, 46

Open die molding, 115-16

Open-hole compression (OHC), 459

Open-hole compression strength, 282

effect of temperature and temperature

and moisture, 283

Open-hole compression testing, 218

Open-hole knockdown factors, 464

Optical fiber buffer coatings, 574

Optical fiber sensors, 533-4, 574-7

connection systems, 534

Optical fiber systems, earliest uses, 534

Optimization algorithms, 568

Orthotropic laminates, 179-80

moduli of, 180-3

stress analysis, 183-5

stress concentration around holes, 191-2

stress-strain law, 180

Orthotropic material, 173

Orthotropic panel under uniform tension,

reference axes for hole in, 205

Orthotropic plate, bending of, 190

Orthotropic ply material for laminates, 564

Orthotropic stress concentration factor, 205

Outdoor exposure, real-time, 280-1

Outer mold line (OML), 158

Painting, 131

PAMFORM, 151

PAMSHOCK, 266

PAN-based carbon-fiber composites, 257-8

PAN fibers, 64-6

Partial impregnation, 163

Particulate MMCs, 16-17

Paste adhesives, 321

two-part, 391

Patch repairs:

adhesives, 390-2

basic approaches, 377

bolted, 397-8, 400-1

bonded, 379-90

carbon/epoxy, 398

design approaches, 379-80

external, 380-6

general considerations, 377-9

installation, 399-401

joint configuration, 380

materials, 390-2

modified load path: 2D effects, 384-5

requirements for, 378

scarf, 385-9

titanium alloy, 398-9

vacuum bag assembly for, 395

Patching techniques, 373-4

s e e also Smart patch

Peel-strength limitation in double overlap

joint, 310-12

Peel stresses, 193-4, 453

methods for alleviating, 312

Phenolic resins, 101-3

advantages and disadvantages, 102-3

cross-linked, 102

pre-polymers, 102

pultrusion, 146-7

Phenylethynyl terminated imide (PETI), 106

Photoelastic fringe patterns, 542

Piezoelectric ceramic actuators, 539-40

Piezoelectric ceramic sensor, 538

Piezoelectric materials, 571-2

Piezoelectric properties, 572

Piezoelectric sensor network, 539

Piezotransducers, 536-7

stress-wave concept, 536-7

Pitch-based fibers, 66-7

properties, 67

Plane stress, 186-90

symmetric laminates, 176-86

Ply-by-ply model, 389

Ply configuration, 6, 331,449

in bolted joints, 339-40

Ply coordinates in thickness direction, 178

Ply orientations, 182

Ply/ply interface, 272

Ply stack for wing rib, 120

Ply strain compatibility, 193

PMR-15, 105, 107

Point strain, 465

Point stress criterion, 206, 341592 INDEX

Poisson's ratio, 23, 31, 173, 180, 183,

192, 216, 267

Polar winding, 142

Polyacrylonitriles e e PAN

Polyaryl sulfone (PAS), 111

Polycarbonsilanepolymer, 70

Polyester resins, 98-100

advantages and disadvantages, 100

curing, 99-100

fire retardant formulations, 99

initiators, 100

pultrusion, 146

types, 99

unsaturated, 98

Polyether sulfone (PES), 111

Polyetheretherketone(PEEK), 9, 20, 87, 109,

251,258, 447

molecular structure, 109

Polyetherimide (PEI), 112, 115, 447

Polyetherketone (PEK), 9, 87, 109

Polyetherketoneketone(PEKK), 109

Polyethylenefibers, 73-4

high toughness, 74

oriented, 73-4

temperature limitations, 73

tensile properties, 73

Polyfluoroethylene(PTFE) film, 235

Polyimide, 9

Polyimide coated fiber in carbon/epoxy

laminate, 533

Polyimide resins, 104--6

advantages and disadvantages, 106

matrices, 87, 105

molecular structure, 111-12

Polyketones, 109

Polymer branching, 82

Polymer matrix composites (PMCs), 13

embedded approach, 527

properties, 81

resistance to interlaminar fracture, 231

Polymeric materials:

mechanical properties, 83-6

overview, 81-3

structure, 83-6

Polymerizablemonomeric reactant (PMR) type

polyimides, 105

Polymerizationprocess, 83

Polymethacrylimide(PMI) polyimide foams,

115

Poly pam-phenylene terphalamide (PPD-T), 72

Polyphenylenesulfide (PPS), 109-10, 258, 447

Polysulfone (PSU), 111, 251

Polyurethane modelling board, 160

Polyvinyl alcohol (PVA), 62-3

Polyvinyl chloride (PVC), 115

Post-buckling performance, 566-7

Potting repairs, 374

Precursors, 56, 83

preforms, 7

permeability, 134

Premier 1 fuselage, 438

Pre-preg, 87, 113

chemical tests, 405

cutting and knitting, 119-21

dispensing machines, 115

materials, 158, 392

production, 118-19

tests, 404

thickness for unidirectional materials, 119

transport and storage, 119

Pre-preg stacks, automated forming, 121-2

Primary Adhesively Bonded Structure

Technology (PABST)program, 294

Primary amine-epoxy reaction, 93

Primers, 63

Process control, 407

Process modelling, 149-57

advanced composites, 150

curing, 152-3

experimental validation, 157

forming, 150-1

heat transfer, 152-3

overview, 149-50

pultrusion, 153

reinforcement stacks, 150-1

residual stress, 156-7

Process verification, 406-7

Processors, 525, 527

Proof tests, 486

PTFE film, 235

Pull-out, 49, 51

Pultrosion, 113-14, 145-9

applications, 149

docking system, 148-9

epoxy resins, 147

in-feed system, 147

key stages, 147

overview, 145-6

phenolic resins, 146-7

polyester resin, 146

process modelling, 153

pulling system, 148-9

reinforcements, 146

thermal equilibrium, 148

thermoplastics, 165

thermosets, 165

tooling system, 147-8

transient time, 147

Pultrusion Dynamics Technology Center, 148

PVDF polymer films, 572

Quality assurance, 403-33

Quality control, 403-8

raw materials, 403-6

Quasi-isotropic laminates, 183, 496INDEX 593

R ratio, 267, 273

Race-tracking, 135, 137

Radiography, 416, 422

real time, 424

Rail shear test, 222

Random copolymer, 82

Ratio of joint strength to basic laminate

strength vs. ratio of bolt diameter to

strip width, 343

Reduced stiffness coefficients, 173

Regular copolymer, 82

Reinforcement:

consolidation of, 155-6

materials, 448

pultrusion, 146

Reinforcement stacks, process modelling,

150-1

Relative humidity and moisture absorption,

280

Repair:

application technology, 394-5

assessment, 369--71

classification of types of structure, 371

in situ, 394-5

joint preparation, 392-3

materials engineering aspects, 390--4,

398-401

non-patch, 373-7

requirements, 371-3

see also Patch repairs

Repair levels, 372-3

Repair options, flow diagram, 373

Repair procedures:

for major damage, 374

non-patch repair for minor damage, 373

Repair technology, 369--402

Residual compression strength vs. impact

energy, 266

Residual strength, 456-7

and BVID, 265-6

function of spectrum cycles, 276

and impact damage, 457

improving, 494

measurement of, 227

reduction under spectrum loading, 275

testing, 230

Residual stress, process modelling, 156-7

Resin content, 405

Resin film infusion (RFI), 87, 137-8, 497

applications, 137-8

tooling, 158

Resin flow through fiber reinforcement,

153-5

Resin injection repairs, 375

Resin molding techniques, 132-40

Resin pressure equation, 155-6

Resin transfer molding (RTM) process,

87, 102, 105-6, 132, 440, 459, 492

advantages, 135-6

applications, 135-7

complex hollow section, 136

fiber-wash, 133

gating arrangements, 135

high injection pressures, 133

isothermal dynamic viscosity curves, 134

materials systems, 133-4

pot-life, 133

preforms, 133

rectilinear mold, 139-40

sequential predicted flow fronts, 155

tooling, 134-5, 158

vacuum-assisted, 138

Resins, 83

testing, 404

Rigid rings, 83

Riveted joints, 290, 362

design detail, 550

Robot-drilling, 132

Robotic CNC filament winders, 142

Robotic painting, 131

Rod and beam elements, 565-6

Roll-forming, 164

Rosen model of cumulative damage, 39-42

Rotorcrafi applications, 443

Routing, 132

Rovings, 74

Royal Aircratt Factory, 477

Rubber, 84

Rubber bladder expansion, 129

Rubber die, 168

Rubbery state, 94, 100

Rule-of-mixtures prediction, 37

Rule-of-mixtures relationship, 26

Safety factor, 477

Saint-Venant principle, 184

Sample cross-section and strength

distribution, 56

Sandwich construction, 114, 222

Scale effects, 215

Scarf repairs, 385-9

failure of loads and strains for carbon/

epoxy, 388

honeycomb panel, 385

shear stress distribution, 389

vacuum bag, 396

Second deviatoric strain criterion, 201-2

Secondary amine-epoxy reaction, 93

Self-healing, 18

Self-similar propagation, 52

Sensors, 525, 527

Sewing machine, 492

S-glass, tension-tension fatigue results, 252

S-glass composites, 241,436

costs, 242594 INDEX

S2 glass, 436

Shape adaptive structures, 541-2

Shape memory alloys (SMA), 540-3, 573-4

Shape memory effect, 573

Shaped panel molding, 167

Shear modulus, 182

Shear-out failure in mechanically fastened

joints, 345-6

Shear stress, 193

parallel to fibers, 46

Shear stress distribution:

in adhesive, 308

scarf repairs, 389

Shear stress/length distribution in adhesives,

307

Shear testing, 222-3

Shearography, 417, 427

Shimming, 364-5

SIFT, 200-1

applied to laminates, 202

failure envelope for polymeric materials,

204

matrix failure envelope, 203

Silica fiber/aluminum matrix composite, 12

Silica fiber-reinforced aluminum, 11

Silicon carbide:

coatings, 18

elastic modulus, 70

Silicon carbide fibers, 69-71

based on polymeric precursor, 70-1

chemical compatibility, 70

CVD-based, 69-70

manufacture, 70

Silicon nitride coatings, 18

Silicon robber bladder, 117

Simply-supported beam, bending of, 189

Single ply, 171

laminate axes, 174

material axes, 172

modulus data, 181

Six-axis robots, 132

Skin-doubler specimen, 538

Smart behavior of biological structures, 525

SMART layers, 537, 539

Smart patch, 531-3

concept, 531-2

monitoring, 532-3

objectives, 531

Smart structures, 525-47

active, 539-43

actuator properties, 578-9

components, 526

engineering analogies, 527

engineering approaches, 526-31

key technology needs, 544-5

potential applications, 528

selected applications and demonstrators,

531-44

Smart Wing Program, 541-2

S-N curve, 267, 269-70

Solvent resistance, 84

Specimen buckling, 218

Specimen impactor, 230

Splitting in curved beam, 199

Stamp-forming, 167-8

dies, 168

Starch, 62

Static strength, 449, 465, 480

demonstration of, 484-6

design, 481

predictions, 207

vs. clamp-up torque for single-hole

joint, 346

Static strength allowables, 482-3

A-allowable, 482-3

B-allowable, 482-3

Static tests, 213

Steel tooling, 159

Stiffened panels, external patch repairs, 381

Stiffener separation, 195, 566-7

Stiffness, 4, 7, 84

Stiffness analysis, 383--4

Stiffness imbalance in double-overlap joint,

309

Stiffness matrix, uncoupling, 188

Stiffness reduction method, 198

Stitching, 492-8

applications, 497

in-plane properties, 495

mechanical properties, 493-7

modified, 498

out-of-plane properties, 493-4

vs. z-pinning, 501-2

Strain-based failure theory, 199-202

for fiber failure in tension, 199

Strain compatibility, 44

Strain energy release rate, 235, 237, 329-30

mode I, 234-5

Strain Invariant Failure Theory s e e SIFT

Strain response, open-loop and closed-loop,

541

Strain values, 465

Strands, tensile testing, 404

Strength analysis based on adhesive strength,

382-3

Strength distribution and sample cross-section,

56

Strength reduction data, 206

Stress analysis:

bonded joints, 297

orthotropic laminates, 183-5

Stress-based failure theories, 195-9

failure modes, 196-8

laminates, 198-9

Stress concentration, 191,271-2

circular hole in infinite tension panel, 192INDEX 595

holes in orthotropic laminates, 191-2

laminates with unloaded holes, 340-5

Stress concentration factor (SCF), 191

circular hole in tension panel, 192

laminates, 450

Stress distribution, 184

in doublers with scarfed stepped skin ends,

305

Stress effects, 285

glass-fiber composites, 246

Stress failure envelopes for unidirectional

carbon fiber, 197

Stress function, 183-4

Stress intensity factor K, 49

Stress raisers, failure prediction near, 204-7

Stress relaxation, 49, 51

Stress resultants, 178, 187

Stress rupture, aramid fibers, 252-3

Stress rupture strength, E-glass fibers, 246

Stress/strain properties, adhesives, 298, 323-5

Stress-strain law, 171

laminates, 179

orthotropic laminate, 180

orthotropic material, 173

single ply in laminate axes, off-axis

laminates, 174-6

Stress-strain law, single ply in material axes,

unidirectional laminates, 172-4

Stress testing, 85

Structural analysis, 171-211

Structural behavior, linear and non-linear, 560

Structural detail tests, 482, 485

Structural health monitoring (SHM), 529-37

Structural reaction injection molding (SRIM),

155

Sub-component tests, 484-5

Suppliers of Advanced Composite Materials

Association (SACMA), 214, 218, 405

Surface blemishes, 131

Surface ply orientation, 331

Surface porosity, 130

Surface treatment:

adhesive bonding, 336

pre-bonding, 393

Surfacing resin film, 130

Swelling strains, 285

Symmetric laminates:

bending of, 188-90

plane stress problems for, 176-86

Tack test, 405

Tapes, 79

Temperature effect, 284-5, 460-1

on adhesives, 331-2

on compression strength, 461

on mechanical properties, 282-4

on weight-gain profile, 281

Tensile failure:

mechanically fastened joints, 342

modes, 42

Tensile matrix failure, 197

Tensile strength:

cross-ply laminates, 262-3

effect of temperature and temperature and

moisture, 283

simple estimate, 36

statistical analysis, 38

Tensile stress:

normal to fibers, 46

parallel to fibers, 46

Tensile testing, failure modes in, 217

Tension, carbon-fiber composites, 260-1

Tension/compression fatigue, 273

Tension fatigue of cross-ply composites, 270-1

Tension-tension fatigue properties, 267-70

Terbium-iron alloys, 577

Testing Pyramid, 215

Tetrachlorophthalic anhydride, 99

Tetraglycidyl derivative of diaminodiphenyl

methane, 88, 92, 94, 97

Tetra-oxirane ring, 98

Textile preforming techniques, 79, 460

Textile technology, 7

Textron Speciality Materials, 248

Thermal expansion mismatch:

in double-overlap joint, 309-10

in scarfjoints, 319

Thermal spiking, 97, 284-5

Thermography, 417, 424-6

fatigue loaded specimens, 232

Thermoplastic matrices, 447

materials used in aerospace composites, 90

Thermoplastic polymers, 9

Thermoplastics, 83, 108-12

aerospace-grade, 88

amorphous, 108

fabrication, 87

filament winding, 143-4

fusion repairs, 376

intermediate material forms, 162-3

matrix materials, 86-8

processing technology, 163-8

properties, 86-8

semi-crystalline, 108-9

special techniques, 162-8

sulphur-containing, 110

see also specific materials

Thermosets, 9, 83-4

matrices, 478

matrix materials, 86-9

properties, 86

see also specific materials

Thermosetting resins, 88-107

filament winding, 143

properties, 87596 INDEX

Three-dimensional textile manufacturing

techniques, 492

Three-dimensional woven carbon--carbon

preforms, 505

Three-dimensionally reinforced preforms and

composites, 491-524

overview, 491-2

Through-thickness failure, 195, 198-9

Through-thickness strength, 451-3

Time-temperature-transformation diagram,

94-5

Titanium alloy, 1, 20, 239-40, 440

MMCs, 15

patch repairs, 398-9

Titanium aluminide MMCs, 15

Tooling, 158-62

ACG "Toolbrace", 162

airpad brand inflatable, 161

closed-mold, 158

composite materials, 159-61

materials selection, 158

metallic materials, 158-9

open-mold, 158

Top-hat stiffened component, 117

Toughening agents, 95

Toughness, 4

Tow placement, 113-14

Tows, 74, 149

Transverse expansion coefficient, 34-5

Transverse failure, 194

Transverse modulus, 23, 32

Triglycidyl derivative of p-aminophenol

(TGAP), 88, 92, 94

Trimming, 131-2

Tsai-Hill criterion, 340

Tsai-Hill theory, 195

Tsai-Wu Theory, 196

Tungsten alloy wires, 16

Ultimate failure, 194

Ultrasonic insertion gun, 500

Ultrasonic inspection, 416, 419-22

non-contact, 424-5

Ultrasonic vibrator method of z-pinning,

500

Ultraviolet damage, 285

Unidirectional composites:

buckling mode, 45

crack propagation, 48-9

failure modes, 45

fracture toughness, 47-52

properties of, 240

tensile strength vs. orientation, 47

Unidirectional laminates, 172-4

Unidirectional ply, model and representative

volume element, 27

Ureol tooling, 160

U.S. Department of Defense Military

Handbook see MIL-HDBK 17

U.S. Federal Aviation Authority (FAA), 479

U.S. Navy (USN), 477-8

USAF B-2 bomber, 438

V-22 tiltrotor, 443

Vacuum-assisted RTM (VARTM), 102, 138

Vacuum bag:

lay-up, 125

scarf repair, 396

Vacuum bag assembly for patch repairs, 395

Vacuum bag resin infusion (VBRI), 158

Value engineering, 466-74

Value indices for fighter aircratt, 473

Van der Waals bonding, 63

Vibration damping, aramid fiber composites,

255

Vinyl ester resins, 101,251

formation, 101

Visible impact damage (VID), 455

Voids, formation, 129

Von Mises yield criterion, 195-6

Weaving, 7, 448

structural modelling, 564

three-dimensional, 502-5

applications, 506-7

architectures, 503

in-plane properties, 505-6

mechanical properties, 505-6

out-of-plane properties, 506

see also Woven fabrics

Weibull distribution, 39

Weibull statistics, 55

Weight changes for unpainted composite

coupons, 281

Weight-gain profile, temperature effect on, 281

Weight ratio:

airframe materials, 471

equations for failure categories, 470

Weight saving:

cost value analysis, 469-74

function of failure mode, 467-9

through increased specific strength or

stiffness, 3

Wet laminating procedures, 116

Wet-winding procedure, 141

Whirling winding, 142

Whiskers, 6-7

World War I, 477

World War II, 435

Woven carbon/epoxy composites, effect

of impact energy on compressive

strength of two-dimensional and

three-dimensional, 507INDEX 597

Woven fabrics, 77-8

Wrapping, 117

XAS/914C laminate:

compression residual strength, 275

impact damage, 265

X-ray probe, 425

Yams, 74-7, 113, 492

tensile testing, 404

three-dimensional weaving, 503

z-direction, 503

Yield stress, 478

Young's modulus, 65-7, 173, 176, 180, 183

glass-fiber composite, 242

and temperature, 85

Z-pinning, 498-502

foam method, 499

mechanical properties, 501

process, 499

ultrasonic vibrator method, 500

vs. stitching, 501-2

Z-reinforcement, stitches for, 49

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل كتاب Composite Materials for Aircraft Structures

رابط مباشر لتنزيل كتاب Composite Materials for Aircraft Structures

|

|