Admin

مدير المنتدى

عدد المساهمات : 18864

التقييم : 35108

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

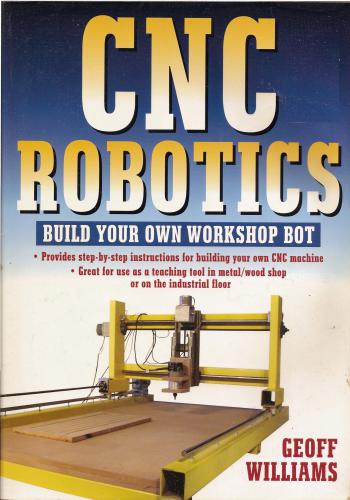

|  موضوع: كتاب CNC Robotics - Build Your Own Workshop Bot موضوع: كتاب CNC Robotics - Build Your Own Workshop Bot  السبت 13 مايو 2023, 2:33 am السبت 13 مايو 2023, 2:33 am | |

|

أخواني في الله

أحضرت لكم كتاب

CNC Robotics - Build Your Own Workshop Bot

Geoff Williams

و المحتوى كما يلي :

Contents

1 Design 1

Why Build My Own I

Gantry Style 2

Motors 2

Lineal Motion 4

Motor Drivers 9

Acme Screw 9

Deciding on the Dimensions of the Machine 9

Software 10

2 Electronics 13

Stepper Motor Driver and Computer Interface Boards 13

Stepper Motor Driver Circuit 15

The Interface Board 19

3 Making the Printed Circuit Board 77

Tools and Material 77

Artwork 78

Board Cutting and Cleaning 82

Toner Transfer 85

Etching 93

4 Driver Assembly 99

The Interface Board III

vGNG Robotics

5 Softwa re Setup and Driver Testing 113

Material Needed 113

Creat ing Test Files 121

Triangle Test 122

Circle Test 123

Putting the Elect ronics in a Case 124

6 The Frame 133

Tools and Ma terial 133

Bolting 138

Assemb ly 141

Bearing Ra il Support Bolt Holes 144

Paint the Frame 151

7 The Gantry and X-axis 1 53

The Gantry 153

The X-axis: Installing the Gantry Bearing Guide Rail 160

Beari ng Holder 164

8 The Z and Y Axes 175

The Z-Axis 175

The Y-Axls 184

9 Motor and Lead Screw Insta llat ion 189

Tools and Ma teria l 189

X-axis 190

Y-axls 199

Z-axis 203

Limit Switc h Install ation 206

X -axis Limi ts 208

Y-axis Limi ts 209

Z-axis Limits 211

10 File Creation and KCam 215

KCam CNC Control ler Software 215

KCam File Requirements 219

How to Create a File to Import 222

CorelDraw 223

ACME Profile r 239

viContents

11 Tool Holders and Testing 245

Tool Holders 245

Penholder Tool 246

Router/Dremel Holder 252

Testing the CNC Machine 257

12 Examples 263

Plotter 263

Mechanical Engraving Tool 268

Dremel Tool 271

Ma ster Craft Rotar y Tool 274

Router 278

Sources of Material 293

Electronic Components 293

L297 /L298 Integrated Circuits 293

CANADA 293

United States, California 294

Lineal Motion 296

Distributor 296

Manufacturers 29 7

Stepper Motors 300

Metal 301

Index 303

x

Note: Boldface numbers indicate illustrations.

ACME Profiler, 239 -243 , 240-242

acme screw, 9

Arrow Corporation, 292, 293

AutoCad, 12

AVNET Corpo ration, 293, 294

back EMF, in motors, 73-74

bearing guide rails

bearing holder in, 164- 173, 165-17 3

boll ho les in, 144- 150, 144- 150

X axis, 160- 164, 161- 164

Z axi s fit and, 182, 182

beari ngs. lineal motion. 8

bipo iar motors, 48, 59, 64

Bishop- W isecarver Corporation. 296

bo lti ng the fra me together, 138- 140, 138 - 141

cabinetry, 281 -292

Canad ian Beari ngs Ltd" 295

capacitor installation in driver, 109-110, 110

case enclosure for electronics. 124-1 32, 125. 132

changing bi t size, 236, 237

chopper co ntro l and ci rcuit, 54- 5 7, 54 , 55, 56, 65, 66-67, 67

ci rcl e test fil e, 123- 124, 124

cleaning steel, 137, 137 , 138

cl eaning the pr inted circuit board , 82-84 , 83, 84

cl ock pulse do ub ler, L297, 59

303304

CNC Robotics

CNC controls setting, 11 7, 11 7, 120, 120 ,218-219, 218, 219

computer connection

driver and interface board, 118-120, 118, 119

interface board between motors and. 13-15 . 13

interface board to limit switches. 19- 21. 20

continuity checking . 107

contro ller software, Ke arn, 215-2 19

controllers. motor, ST M icroelectronics manual on (Seealso L297; L298). 22-75

CorelD raw, I I, 12, 223 -239 , 223

exporting fil es to KCam fro m, 226, 22 6, 227, 22 8

KCam use of, 224, 225, 226

layout options for, page size, shape . etc., 224, 225

offsetting G code to center the project, 238, 238, 239

texttes t.plt file in, 233, 234 , 234

vector grap hics V5. raster graphics in, 238-239

cost of CNC machines. 1- 2

cutting depth settings, 258

cutting steel , t 36, 136

cutting the printed circuit board. 82-84. 83 . 84

Data Exchange File ISee also DXF files) , 223

design, 1- 12

acme screw in. 9

dimensions in. 9- 10

front view, JJ

ganl ry sty le in, 2

lineal motion in, 4-8

motor drivers, 9

motors for. 2-4 , 3

side view, 10

software selection. 10-1 2

dimensions of machine, 9- 10

doo rs, 281- 282, 281, 28 2

dovetail jo ints, 283-286, 283, 284, 28 5, 286

Oremel tool

engraving with, 271- 274, 271-2 73

holder for, 252- 257 , 252-2 5 7

dr illing holes in PCB, 100-101 , 100, 101, 10 2

drills, 100, 100

driver, motor, 9. 15- 19. 17. 99- 112

bottom ar tw or k for, 79-80, 79

cables for, 128, 129

capacitor installation in. 109-110, 110

component placement and installation in. 104-108 , 105, 106

continuity checking in. 107

dr illing holes in , 100-1 01, 100, 101 , 102

finished product, 112

headers for, 108- J09, 109

heat sink for, III, IIIIndex

driver, motor (continued)

interface board connection to. 11 8- 120, 118, 119

interfa ce board for, 111 - 112, 112

L298 ins talla tion in, 109, 109

leads in, 108

materials and tools for, 99 . 100

mo therboa rd mounting of, 126, 126

power supply for, 11 8

soldering in, 101, 103, 103

static electricity protection in, 104, 104

testing, 113- 132

top of driver boa rd, 80, 80

w iri ng , 110- 111, III

DXF file s, 12, 219, 22 2-22 3

electronics, 13-75

case enclosure for, 124- 132, 125, 13 2

interface bo ard, 19- 21 , 20

interface boards, stepper motor driver and computer. 13- 15, 13

source s, 29 3-296

stepper motor driver circuit. 15-19 . 17

engravlng

Drcmel tool for, 271 -2 74, 271-2 73

engra ving tool fo r, 268- 271, 268 - 27 1

Mas ter Craf t rotary tool for, 274-277, 274-277

etch ing process in PCB, 93-97, 93, 95, 96

Exellon fil es, 219

fan, 125, 128- 129

file format s, in programming, 12

frame, 133- 151

assembly of, 141 -144, 141, 142, 143

bearing rail support bolt ho les in , 144-150, t 44-1 50

bolting together, 138- 140, 138- 14 1

clean ing, 137, 137, 138

cutt ing steel for, 136, 136

dimensions of. 133- 134, 134

pa in tin g, 151

squa rin g and levelin g of, 141 -i 44, 141

tools and materia ls for, 122- 125

we ldi ng together, 143- 144, 143

front view of CNC machine, II

Future Electronics. 293, 294

G code , i i, 219

ga nt ry, 2, 153-160, 154

bear ing ho lde r in , 164- 173, t 65 -1 73

bol t ho le locations in, 157 - 158, 158, 159

mounting and access hol es on uprigh ts, 156, 156, 157

305306

CNC Rob otic s

gant ry (continued)

spanning beams for. 155-1 56. 155. 156

tools and materials for, 153

upr ights and feet for. 155. 155. 159-1 60. 159 . 160

X ax is in . 160- 164. 161-164

Gerber fil es. 219

glass etching. 266- 26 7. 266. 267

guide rail s. 7. 7. 8

half- step sequence, in motor, 52, 52

heat sink for driver. 111, III

Hew lett Packard Graphics Language (Sec also HPGL files) . 222

HPGL files. 12. 21 9. 222- 223

import file creation for Ke arn, 222-223

INA Inc.• 296

in terface board. 19- 21 . 20

artwork for, 80, 8 1

cables for. 128. 129

driver board connection to. 118-120, 11 8, 11 9

motherboard mounting of. 127. 127

stepper motor driver and computer. 13- 15. 13

joints. cabinetry. 283-286. 283. 284. 285 . 286

KCam and programm ing . 11- 12. 12. 13

ACME Profil er and . 239-243. 240-242

AutoCad in, 12

changing bit size and . 23 6. 23 7

CNC con trol selling in. 218-2 19. 218. 219

CNC Controller softw are for. 215- 219

converting text to curves in. 23 7, 237

CorelDra w and. II. 12. 223-239 . 223

cutting depth settings in, 258

downloading cop y of. 11 3- 11 4

file formats in . 12.219- 222

G code and com mands fo r. 11 . 21 9- 221

impo rt file creati on for, 222 - 223

insta llat ion of. II 3. 215

lathecorej .plt fil e. 28 7- 291

li netest. plt file in. 228 -230. 230

Iinetest2 .plt fil e in . 231 - 232. 233

M code and commands for, II, 220-222

machine setup file for. 258

offsetting G cod e to center the project. 238. 238. 239

openi ng. 21 5

port assignment in, 216, 217

shapes.plt file for. 261-262. 26 1. 262

software selectio n, 10-1 2Index

Kearn and programming (continued)

system timing in , 217, 217

Table Setup w indow in, 215, 216

testtexl.plt file for, 260, 260, 26 1

textt est.plt file in , 233, 234, 234

tool size setting in, 234, 235, 236

user defined M codes for, 222

KellyWare (See also KCam), 113

L297 stepper motor con troller, IS , 18- 19,22- 75,22, 23 ,46

a version of (L297A), 57-58, 58

advantages of, 46-47

applicalion for, 29

bipolar steppe r motor and, 59

block diagra m of, 23

circuit operation in, 2S

clock pulse doubler In, 59

DIP packa ge mechanical data for, 30- 31, 30, 31

electrical characteristics of, 27- 28, 28

half step mod e in, 26, 26

L293E vs. 47

normal drive mode in, 26. 26

phase sequence in. 26

pin connections for. 23 , 62

pin function chart for. 24- 25

pin functions for, 61

sources for, 29 2

synchroni zation in. 29

unipolar motors and , 59

wave drive mode in. 27, 2 7

L298 H br idge IC, I S, 18-19, 33- 75, 33

application informat ion in. 39

bidirectional control in. 38 . 40

block diagram of , 33

dimension data for. 42, 4 2

electrical cha racteristics of, 35 -36

installing in driver, 109. 109

ma xim um rat ings tor, 34

muiti watt ISH, 43, 43

multiwatt 15V, 42, 42

PCB layout for, 4 1

pin connections for. 34

pin funct ions for, 35

PowerS020, 44, 44

satu ration voltage in, 36

sink current in, 38

sources for, 29 2

sw itching times in, 36, 3 7

thermal data on, 34

307308

CNC Robot ics

lath e, 286-292, 287

lathecore3.plt file, 28 7-291

limit switch

installa tion, 206-21 4, 207 , 208

interface board to computer. 19-2 1, 20

lineal motion . 4-8

bea rings in, 8

guide rails in. 7. 7. 8

suppliers of mat er ial for, 296 -300

TV gli de tray assembly in, 8

Iinetest.plt file, 228-230, 230

linetest2.plt file in, 231 -232, 233

load current regulation. motor, 53-54. 54

losses. motors, 68

M code, II , 220-222

machin e setup file. Ke arn. 258

Mas ter Craft rotary tool engraving, 274-277 . 274- 277

materials, sources, 29 3-301

MDF as table board, 25 7, 258

mechanical engraving tool, engravings. 268- 271, 268-2 71

Me tal Supermarkets, 300

metal , suppliers of, 300

motor mo unts, 190, 190 , 191 , 19 2

motors, 2- 4 , 3 , 14

back EMF and, 73-74

bipolar, 48, 59 , 64

cable connection s to, 130- 131, 130 , 13 1

chopper contro l fo r, 54- 57, 54, 55, 56, 65, 66 -67, 67, 70- 73, 71

controllers for, ST M icroelectronics manua l on (Seea/so L297; L298). 22-75

drive top ology select ion for, 64-6 5, 64

dri ver for, 9, 15- 19, 17

flexi ble shaft coupling for, 198, 198

half step drive, 49, 52, 52

installation of. 189-2 14

interface board to comp uter and. 13- 15. 13

L29 7 step per motor co ntroller Ie for (See also L2971, I S, 18- 19, 22-75,

22, 23

L298 H bridge IC (See also L298), IS, 18- 19, 33-75, 33

lead screw centering and mounting. 193- 196. 193-196. 197

limit sw itch installa tion for, 206- 21 4, 20 7. 20 8

load current regulation in, 53-54 , 54

losses in, 68

minim um current in. 68 , 69

mounts for. 190. 190. 191. 19 2

noise and , 70-73 , 71. 72, 73

peak detect current in, 68. 69

phase sequence generation in, SO-53. 51. 5 2. 53

power dissipation in bridge Ie in. 68 . 71Index

motors (continued)

power supply for. 4. 15

problem s and soluti ons for. 64-75

ripple current in. 68

selection of, unipolar Y5. bipolar, 64

sources for used/ second-hand, 4

stepper motors, 4 8

stuck condition in. 74

suppliers for. 300- 301

tools and materia ls for installation of. 189

two pha se drive in . 49 . 52. 52

unipolar. 48. 50 . 60. 64. 66

variable reluctanc e, 50, SO

wa ve drive state sequence in, 53. 53

wind ing current in. 69, 70

w iring diagram for, S

X axis and. 190- 199. 193

X axis limit setting for. 208-209. 208. 209

Y axis and. 199- 203. 199-203

Y axis limit sett ing for. 209 -210. 210

Z axi s and. 203-206 . 20 4- 206

Z axi s li mit setting for. 211-2i 4. 211-214

Mo user Electron ics. 294

noise, in motors, 70-73, 71, 72, 73

NSK Inc.• 297

NU Horizons Electronics, 294

NuArc Model SST 1418 hori zontal camera. exploded view. 6, 7

Pacifi c Scient ific , i 3. 15.299

pain ting the frame. 151

peak detect current. in motors, 68, 69

pen holder, 246-252. 246- 252

phase sequence generation in motors, 50-53, 51, 52 . 53

Pioneer Standa rd. 293 . 295-296

plotter. 263-268, 26 4, 265

port assignment. 11 5. 116, 11 6. 118, 21 6.2 17

power supplies, 4, 15. 11 8, 129

connecting. 128, 128.

connector strips for. 127, 12 7

fan connection to, 128 -129

wi ring diagram for motors, S

Princess Auto, 13, 299

printed circuit board construction. 77- 97

aligning the artwork for, 85 , 85. 8 6

art work for, 78-82

bottom of driver board, 79-80. 79

cleani ng, 82-84

cutting, 82- 84

309310

CNC Robotics

printed circuit board construction (continued)

drilling holes in , 100- 101 , 100, 101, 102

etching process in, 93-9 7, 93, 94, 9 5, 96

interface board, 80 . 81

materials and too ls for, 77, 78

photo resist process in. 78

printing th e artwork for, 80-82

soldering in, 101, 103, 103

static electricity protection in, 104, 104

tinning in, 96. 9 7

toner transfer process in, 85-92 , 87 , 88, 89, 90, 91,92

top of driver board, 80, 80

printers, for PCB construction. 80-82

programming (See KCam and programming)

raster graphics, 238 - 239

read y rod, 9

Richardson Electro nics. 293. 295

ripple current. in motors. 68

rotar y tool eng raving (Master Craft), 274-2 77, 274- 277

route r

holder for, 252 -25 7, 252-25 7

routing with , 278 -292, 278-292

Sanyo Denki, 16, 300

shapes.pit file , 26 1- 262, 261, 262

side view of CNC machine. 10

sign makin g. 278-28 1, 278-280

SKF Inc., 298-2 99

software setup and driver testing. 10- 12, 113-13 2

case enclo sure for electronics and , 124- 132, 125, 132

circle test tile in, 123- 124, 124

CNC co ntrols sett ing in , 117, 117, 120, 120

Kea rn installat ion for. 11 3-11 4

materials nceded for. 113

port assignment in. 115. 11 6, 116. 11 8

Square-gc.txt test file for, 121, 122

steps setting System Timing window for, 114-1 15. J14. J15

test file creation in. 121- 122

triangle test file tor, 122- I 23, 123

solder ing, 101, 103, 103

sources of materials, 293-301

springs tor tool holders, 249 , 250

Square- gc.txt test file, 121, 122

stained glass w indow plotter, 263 - 268 , 264

static electricity protection, 104, 104

stepper motor (See motors)

steps sett ing (table setup) tor motor, 116- 117, 117

system timing, 114-115 , 114, 115, 217,217Index

Table Setup w indow, 215, 216

test tile creation. 121 - 122

testi ng the CNC machi ne, 25 7- 262

testtext.plt file, 260 , 260, 26 1

texttest.plt file, 23 3, 234 , 234

THK Inc., 298

Thompson Ind ustries, 299- 300

tinning th e PCB, 96 , 97

toner tran sfer process in PCB, 85- 92, 8 7. 88. 89, 90, 9\, 92

tool holders, 245- 285

Dremel tool holder. 252- 257, 252-257

pen holder, 246-252, 246-2 52

rou ter holder, 252- 257, 25 2-25 7

springs for, 249, 250

tool size setting in KCam, 234, 235, 236

tr ian gle test file, 122- 123, 123

TV glide tray assembly, li neal motion. 8, 175, 176

two - phase sequence, in motor, 52, 52

un ip olar motors, 48, 50, 60 , 64, 66

user defined M codes, 222

variable reluctance motors, 50, 50

vector grap hics , 238-239

wa ve drive state sequence, motor, 53 , 53

w elding th e frame together, 143- 144, 143

wi nding current, in motors, 69, 70

X axi s, 160-1 64, 161-1 64

limi t sett ing for, 208- 209, 20 8, 20 9

motor installation and, 190- 199. 193

Y axis, 184- 187, 185-1 8 7

limit sett ing for. 209- 210, 210

motor installation and, 199-203, 19 9-203

tools and materials for, 184 - 185

Z axis mounting holes for, 185, 185

Z axi s, 175-1 84, 176

acme screw location in. 181, 181

bearin g ho lde r fit and. 182, 182

centering and mounting, 182- 184, 183 , 184

li mit setting for, 211 - 214, 211 -214

motor installation and. 203- 206, 204- 206

tools and materials for, 175

TV gli de tray for, 175, 176

Y slide atta chment in, 177, 177 , 185, 18 5

z tool mounting surface for, 180 - 181 , 180, 181

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل كتاب CNC Robotics - Build Your Own Workshop Bot

رابط مباشر لتنزيل كتاب CNC Robotics - Build Your Own Workshop Bot

|

|