Admin

مدير المنتدى

عدد المساهمات : 18733

التقييم : 34733

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

|  موضوع: كتاب 3D Printing for Product Designers موضوع: كتاب 3D Printing for Product Designers  الجمعة 17 فبراير 2023, 11:48 pm الجمعة 17 فبراير 2023, 11:48 pm | |

|

أخواني في الله

أحضرت لكم كتاب

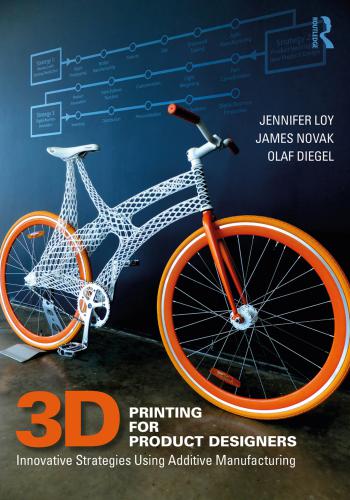

3D Printing for Product Designers

Innovative Strategies Using Additive Manufacturing

Jennifer Loy, James Novak, and Olaf Diegel

و المحتوى كما يلي :

Contents

List of figures viii

List of tables xv

Acknowledgements xvi

Author biographies xvii

Introduction 1

1 Demystifying 3D printing processes and workflow 12

2 Working with a design for additive manufacturing (DfAM)

consultancy 52

3 Strategy 1: Working with existing production 67

4 Strategy 2: Product redesign and new product design 96

5 Strategy 3: Digital business innovation 122

6 Case studies: 3D printing from the product designers’

perspective 145

7 DfAM: Design guidelines for product designers 207

8 3D printing sustainability and digital ecosystems 244

9 Making the future/remaking product design 266

Glossary of terms and acronyms 275

Notes on organisations, companies, and designers 278

Index 281viii u

List of figures

1.1 A new framework for additive manufacturing technologies

for product designers. Solid boxes/circles indicate overlap

with the ISO/ASTM 52900 standard categories of additive

technologies 17

1.2 Close-up detail of the layers on a dual-material 3D print

produced on a desktop FFF machine using 0.2 mm layer

thickness and a PLA material (grey) and TPU (white) 22

1.3 Stereolithography (SLA) – laser cured resin with internal

resin support structure (Loy) 23

1.4 Multiple material, full-colour material jetting technology used

for medical models as communication and planning tools,

such as on the Mimaki printer (a) and on a Connex (b) 25

1.5 HP Multi Jet Fusion (MJF) colour sample that is cut open to

show interior grey colour 25

1.6 The three main processes required to go from CAD to 3D print 26

1.7 A solid model of a tube in CAD software (a) compared to a

low-resolution STL (b) and high-resolution STL (c) 28

1.8 The two core components of an OBJ file are the 3D mesh

file (a) and PNG image file (b) that combines into a full-colour

model (c) 29

1.9 The same STL file with error in two different slicing

programs, with only one of them clearly indicating a

problem through red colouring 31

1.10 Mesh repair software can be used to highlight and correct

problems in 3D print files, in this case overlapping triangles 32

1.11 A mesh hole (a) which has been repaired to follow

surrounding geometry compared with a more organic

addition (b) that does not suit the designers’ intent 33

1.12 Typical file conversion stages from CAD to 3D printer 34

1.13 Imported STL (a), sliced model (b), and detail of some of the

slices showing the pathway of the print nozzle (c) 35

1.14 Setting up different supports for a Selective Laser Melting

(SLM) process 35ix u

List of figures j

1.15 Process of removing the “cake” from the SLS printer and

then removing parts by hand on a table with a built-in

vacuum to collect powder 41

1.16 Blast cleaning the parts and detail of a part with fine details

where blasting does not completely remove excess powder 41

1.17 Handle manufactured in stainless steel using selective laser

melting (Loy) 46

1.18 Handle showing support material from the selective laser

melting process 47

1.19 Multiple prints attached to the base plate (top); manual

removal of support material (bottom) 48

1.20 Small test pieces for understanding support material

strategies for metal printing 49

1.21 Creating an assembly with metal printing is possible

and requires an understanding of support placement (a)

and tolerances, informed by an understanding of post

processing (support structures removed) (b, c) 50

2.1 Mapping the technology adoption journey 54

3.1 Overview of Strategy 1 approaches to 3D printing 67

3.2 68

3.3 Example of rapid prototyping – MagnaLatch Series 3 pool

safety gate latch 72

3.4 Example of bridge manufacturing: drug delivery storage container 74

3.5 Example of fixtures for welding 77

3.6 Example of a jig – angled drilling jig to achieve a precise

31.6° angle 82

3.7 Example of enhanced tooling – conformal cooling channels

shown through both cross-section (left) and transparent

print (right) 86

3.8 Example of agile manufacturing – a one-off mould for

vacuum forming utilising a 3D scan of someone’s face, to be

used for some chocolate moulds 88

3.9 Example of a positioning jig 94

4.1 Overview of Strategy 2 approaches to 3D printing 96

4.2 97

4.3 Example of part consolidation – guitar holder and guitar stand 104

4.4 Example of light-weighting – Atlas Copco Hydraulic Manifold 106

4.5 Example of customisation – topology-optimised walking

frame lugs 111

4.6 Example of form determined by function – Canal House wall

construction 114

4.7 DUS Architects 3D printed formwork creates voids that can

then be filled with different materials, such as concrete or pulp 115

4.8 Example of product innovation – Tuber9 light series 117x u

j List of figures

4.9 Fox Coral Solutions can now supply their traditional aftermarket motorcycle parts like foot pegs (green), while also

providing customised 3D printed inserts (orange) that can

be sold as part of the package, or individually curated

by riders online 119

5.1 Overview of Strategy 3 approaches to 3D printing 122

5.2 123

5.3 Example of a digital inventory project – parts digitised,

redesigned, and validated in Australia for 3D printing,

then 3D printed in Nairobi, for the Oxfam G.B.

WASH project 125

5.4 Example of a distributed manufacturing context – low-cost,

open-source 3D printed face shield called the RC3, designed

by Prusa Research (Novak) 128

5.5 Example of personalisation – Child’s Play prosthetic made to

fit an arm scan 131

5.6 3D scanning interfaces are becoming easier to work with,

and a wider range of equipment is now available 132

5.7 Example of the creation of an adaptable system – Nodal Design 134

5.8 Example of an automatically generated race car spaceframe

from a solid CAD model 136

5.9 Example of digital business innovation – Prosfit, led by Alan

and Christopher Hutchison 138

6.1 A selection of Rehook prototypes 3D printed using desktop

FFF to allow quick and cost-effective iteration (a) SLS

production of Rehook in progress 146

6.2 Evolution of Rehook from prototype to final product 147

6.3 Process of topology optimisation of the seat post bracket

with a final image of the bracket in its printed orientation,

amongst other frame pieces on a build plate 148

6.4 Complete 3D printed titanium bicycle frame from Empire

Cycles and Renishaw 149

6.5 Compression testing of early lattice sample (left),

comparison of aerodynamic properties of a standard tube

and lattice geometry using simulation (right) 150

6.6 FIX3D bicycle frame 151

6.7 Wind tunnel testing of Dynaero at 44 km/h 153

6.8 Dynaero 3D printed bike helmet and accompanying mobile app 153

6.9 The Atom 155

6.10 FEA analysis showing deflection of original ODD Guitar body

(a), 2nd iteration (b), and 3rd (c) 156

6.11 A production run of Americana and Atom guitars. Each guitar

has features specific to each musician (Diegel) 158

6.12 The Scarab ST full-colour 3D printed guitar (Diegel) 159xi u

List of figures j

6.13 Aluminium guitar still welded to the build-plate, and close-up

showing the support material below the barbed wires (a).

Finished Heavy Metal aluminium 3D printed guitar (b) 160

6.14 The GreenAxe 3D printed wood guitar. Printed in sawdust

and lignin-based bio epoxy using a proprietary binder-jetting

3D printing process 161

6.15 Close-up of Adrian McCormack’s SLS guitar 162

6.16 Marbled finish achieved using hydro-dipping for the SLS

printed guitar (McCormack) 162

6.17 Multiple piece guitar, filament printed 163

6.18 Berto Pandolfo designed the “MND” furniture series

exploring the relationship between the handmade and

machine-made, in timber with 3D printed legs 164

6.19 Fingerprint Stool 165

6.20 Failed print after being dislodged from the build plate

without raft (a) and completed stool in the BigRep ONE

printer (b). 166

6.21 Ghost Chair 168

6.22 Pneumatic, flexible water-creatures by Ross Stevens (a)

and rigid 3D printed prop glove by Tor Robinson and Ross

Stevens of Victoria University, New Zealand (b) 170

6.23 Material jetting, 3D printed, multi-material eyes 171

6.24 3D printed faces based on 3D scan, with 3D printed eye

inserts – see Figure 6.23 171

6.25 Large format 3D printing by Studio Kite: Chariot for the

movie Thor: Love and Thunder; statue and column for

Thor: Love and Thunder prior to finishing 175

6.26 Textile assembly printed as a single part (a), 3D printing

directly on fabric (b) 175

6.27 Examples of SCAN2CAST 3D printed custom splints 178

6.28 Setting up the trim and split lines to automatically generate

a ready-to-print splint 179

6.29 Custom-made, 3D printed decorative splint 180

6.30 Stigma-to-Silver-Linings 181

6.31 Super-abled 182

6.32 Angel Leg 183

6.33 3D printed artery model with stent 184

6.34 Detailed view of a prototype implant housing which was

printed using FFF (a); a collection of different prototypes

can be printed with FFF in <30 minutes at this scale

(b); testing the fit of different sized magnet housing on

different 3D printed skull anatomy (c); a collection of SLS

printed housings to be embedded in the silicone prosthesis

(d); fitting of a prosthetic ear using the magnet systemxii u

j List of figures

over a skin-like silicone sheet (e); detailed view of early

experiments directly gluing magnets into a prosthesis to

match the 3D printed implant design (f) 185

6.35 Experimenting with materials and simple prototypes from

a Stratasys J750 Digital Anatomy Printer to gain feedback

from neurosurgeons about haptic and other qualities

compared with real anatomy 187

6.36 Cartridge system models designed by Liam Georgeson 187

6.37 A final prototype of the EVD training model, along with

some material samples, and a StealthStation navigation

device set up in the background 188

6.38 Topology-optimised mask produced using FFF being fit

tested to a phantom (a, designed by Amirhossein Asfia),

full-colour MJF printed mask featuring light-weight lattice

structure and markers for tracking (b, designed by Faizan Badar) 189

6.39 Intubation simulation with the mask fitted with square filter

housings (left), fit testing with the Halyard qualitative fit

testing kit (right) 190

6.40 Creating samples as a catalogue of digital printing to inform

practice and for communication with clients 191

6.41 Exploring the ability to create form with 3D printing using

SLM, SLS (right), and MJF (left), designs modelled in Solidworks 192

6.42 Exploration of organic form, designed, 3D modelled, and 3D

printed by David Haggerty 193

6.43 Fractilus range of jewellery designed by David Haggerty,

using 3D printing in different ways during the process (a)

direct metal printing, and (b) lost wax casting 193

6.44 Material jetting vases, showing prior to postprocessing

through finishing, and a large example of a print (approx.

height 600 mm and a close-up showing internal detail) 194

6.45 Ball within a ball trophy design and Bling3D earrings/cufflinks 195

6.46 Smallest versions of the earrings (a) and larger size showing

the level of detail that can be achieved (b) 195

6.47 Underside of failed experimental print (a); series of

postprocessing steps (b); finished bracelet designs (c) 196

6.48 Comparison of a conventional mass-produced kitesurfing fin

and 3D printed ABS version (left), 3D printed kitesurfing fin

during early tests on the water (right) 198

6.49 Example range of surf fin shapes that can be generated

algorithmically using Grasshopper and Rhino, with users

interacting with a simple control interface that hides the

complex model processes (a), 3D printed carbon fibre-filled

nylon surf fin, generated algorithmically (b) 199xiii u

List of figures j

6.50 Cross-section through 3D printed heat exchanger 200

6.51 Illustrative example of a single gyroid cell (two versions on

the left) and network of connected gyroid cells (two versions

on the right). The red (hot) zone is kept separate from the

blue (cold) zone 201

6.52 Basic CAD body for a radiator showing 10 separate bodies

that form the radiator sub-components (left) and a diagram

of a heat exchanger (right) 202

6.53 Creation of a gyroid with a cell size and wall thickness to

meet specified heat transfer characteristics (a) with a cross

section of the TPMS (b) 202

6.54 Section view of completed heat exchanger, including hot

and cold fluid zones (a), the printed part showing minimal

support material requirements (b), printed heat exchanger

section (c), and assembly for testing (d) 203

6.55 Using a related workflow to go from a heat exchanger

to a radiator (a). Printed radiator made using same heat

exchanger workflow (b) and cross-sectional view (c) 204

7.1 Cut sample off an HP Jet Fusion 580 machine showing the

difference between the internal fusing agent (dark grey) and

external detailing agent with colour 211

7.2 3D FFF printed lattice structures 221

7.3 Colour test pieces printed on a HP Jet Fusion 580 machine

prior to surface treatment: (a) font and colour testing on

curved geometry, (b) CMYK swatches which can be sampled

through spectrophotometry and compared to digital colours 224

7.4 From left to right: Original CAD model; High resolution

STL mesh; Low resolution STL mesh; Detail showing the

variable spacing between assembled parts and faceted curves 225

7.5 ‘THEY’ principles of support and orientation 228

7.6 Example of packing for the HP Jet Fusion 580 3D printer 229

7.7 Different infill geometries commonly available for FFF 3D

printing. All of these were specified within slicing software 232

7.8 Alternative surface finishes for metal prints – a part that has

been polished (a), and the same part bead blasted with a

more matte surface finish (b) 236

7.9 From left to right: Raw aluminium ring from SLM process

with some support material removed; ring after support

removal, filing, and bead blasting; ring after polishing for five

minutes with a polishing wheel 237

7.10 Test pieces: Support structure for FFF can be difficult to

remove (a); designing to eliminate support structure (b);

complex structures avoiding supports (c) 240xiv u

j List of figures

8.1 Hexa-Phone Amplifier won the iMaterialise 3D Printed Wood

Challenge. It is 3D printed using selective laser sintering,

with the bulk of the powder made up of waste wood product 245

8.2 Australian start-up Polylab developed a screw-based

extruder system which can utilise shredded plastic from

discarded prints, or other waste products, through a hopper

system. In this example, HDPE material is being turned into

a new product 246

8.3 Examples of 3D printing used to repair common household

products: Replacement drawer roller (a), corner joint for

aluminium window screen (b), bracket to retain control

buttons inside a kitchen rangehood (c) 248

8.4 3D printed versions of “inflatables” artwork by Gregor

Kregar, showing support structure on metal 3D print 250

8.5 At-home, desktop 3D printer fridge vent repair 261xv u

List of tables

1.1 Data for tube STL files 28

7.1 Commonly available materials for SLS and MJF 211

7.2 Opportunities and challenges of PBF in relation to the three

strategies of this book 212

7.3 Commonly available materials for FFF and metal extrusion 213

7.4 Opportunities and challenges of FFF in relation to the three

strategies of this book 214

7.5 Commonly available materials for DMLS/SLM and EBM 216

7.6 Opportunities and challenges of metal PBF in relation

to the three strategies of this book 217

7.7 Overview of build volumes for key additive technologies 218

7.8 Minimum distance between moving parts 222

Index

3D scanning 83–84, 131–132, 152–153, 170–171,

176, 188–189

3MF/AMF files 29–30, 223; see also file

Accuracy 28, 79

Aerodynamics 150, 152–153

Agile manufacturing 88–92

Algorithmic design 113, 116, 108–109, 167–168,

198–199

Anatomical model 183–184, 186–188

Animation 116, 141; stop motion 172–174

Anisotropy 80–81, 225

Anodising 232–233

Architecture/buildings 113–115, 134–135

Art 191–195, 250

Assembly printed as one see part consolidation

Automation 133, 135, 139, 179,

227–228, 235

Batch production 146; see also bridge

manufacturing

Bead blasting 40–41, 235–236

Bicycles 145–153

Binder Jetting (BJ) 18, 23, 160–161, 209

Bound metal deposition 213

Bridge manufacturing 74–76, 146–147

Build farm 129–130; see also distributed

manufacturing

Build envelope/volume 37–39, 218–219

Business: education 241–242, 268; future

practice 260–269; innovation 103, 116–119,

137–142, 173

Carbon fibre 79, 198–199

Circular economy 246–247, 258–259, 264

Climate change 256

Co-design 181–182

Collaboration 4, 119, 268–269

Colour printing 22–26, 28–29, 222–224;

full-colour 24–25, 110–111, 159, 169–171,

189, 211, 223–224; multi-colour 24, 222

Computational design see algorithmic design,

computer-aided design, parametric modelling

Computer-aided design (CAD) 26–34, 110, 132, 192

Computer numerically controlled (CNC)

machining 13–14, 53, 237–238; see also

machining

Conformal cooling 86–88, 236

Connectors (e.g., tube and lug) 110–111,

133–137

Consumer/consumerism 140–141, 250–251,

256–262

Continuous liquid interface production (CLIP)

208

COVID-19 4, 89, 127–128, 189–190, 261

Customisation 82, 110–119, 135, 140–141, 150,

177–180, 197–199

Design for additive manufacturing (DfAM) 12–14,

34, 97–99, 108, 207–242

Design thinking 268

Digital inventory 125–127, 272; see also

distributed manufacturing

Digital Light Processing (DLP) 90, 208

Digital thread 248

Dip coating 235

Directed Energy Deposition (DED) 210

Distributed manufacturing 127–130, 137, 150,

253, 263, 272; see also build farm; supply

chain

Dual extrusion/filament 209

Durability 80

Dyeing 211, 234

Education 14, 16–19

Electron beam melting (EBM) 215–216

Index282 u

j Index

Electroplating see metal plating

End-use parts 74–76

Entrepreneur see start-up

Epoxy coating 234–235

Ergonomics 82–83

Extended producer responsibility 247

Fablab 263

Fashion 171, 191; costumes 174–175; see also

jewellery; prosthetics

Filament see Fused Filament Fabrication

File: conversion 26–30; export 26–30, 32, 224–225;

repair 32–33; size 28; types 26–30, 223

Film and special effects 169–176

Finite element analysis (FEA) 111, 156; see also

topology optimisation

Fixtures 77–81

Form follows function 113–116

Furniture 45–50, 163–169

Fused Filament Fabrication (FFF, also called

Fused Deposition Modelling, FDM) 19,

72–73, 163, 165–167, 174–175, 184–186,

198–199, 209–210, 213–215; see also infill

Future: technology 2–5, 269–270

Generative design 108–109, 112–113, 116–117,

167–168, 250–251

Guitars 154–163; stand 103–104

Gyroid 199–204

Health see medical devices, prosthetics

Heat exchangers 199–204

Heat treatment 238–239

Helmets 150–153

Hybrid manufacturing 237–238

Hydrographics (aka. Hydro dipping) 162, 232–233

Implant 184–186

Implicit modelling 178–180, 199–201

Industry 4.0 254–258

Industry 5.0 258

Infill 231–232; see also gyroid

Intellectual property (IP) 127

Inventory see digital inventory

Jewellery 180–181, 192–197

Jigs 81–86

Joining details 220

Lattice structure 109–110, 150–151, 178–180,

189, 191–192, 199–204, 220–221

Layer thickness 219, 230–231

Legislation (e.g., extended producer

responsibility)

Lifecycle assessment 247–248

Lighting 116–117

Light-weighting 106–109, 178, 249; see also

lattice structure; topology optimisation

Logistical postponement 125, 136

Machining 237–238

Market testing 74–76

Material extrusion 209–210, 213–215, 219–220;

see also fused filament fabrication; infill

Materials (e.g., handling, storing) 100–101, 213

Material jetting (MJ) 22–25, 159, 169–171,

193–194, 209

Mechanical properties/tests: compression 150;

cyclic 149; grip 81; rigidity 79; shear 80–81;

tensile 80; wear 81; see also anisotropy;

finite element analysis; orientation

Medical devices 176, 178–180, 183–190; see

also prosthetics

Meshes: mesh modelling 26–29; mesh repair

30–33; see also STL file

Metal 3D printing 35, 44–51, 215–216; see also

bound metal deposition; electron beam

melting; selective laser melting

Metal plating 168, 236–237

Mobile application 153

Moulds (aka. tooling) 86–92; casting 90,

192–193; hybrid 89–90; injection 12–13;

polymer 89; vacuum forming 86, 90

Multi jet fusion (MJF) 24–25, 137–138, 189,

210–211; see also dyeing

Multi-material printing 186–188

Non-fungible tokens (NFT) 252

OBJ file 28–29, 223; see also file

One-off design 154–163; see also agile

manufacturing; personalisation

Open source 128, 197–199, 252

Optimisation see topology optimisation

Orientation 80–81, 129, 225–228; see also

support material

Packing density 228–230; see also build volume

Painting 232–233

Parametric modelling 78–79, 150, 198–199

Part consolidation 50, 103–105, 194–197,

221–222

Personalisation 82–84, 131–133, 152, 165–167,

177–180283 u

Index j

Personal Protective Equipment (PPE) 127–128,

189–190

Polishing 196, 237–238

Post-processing 232–239; SLM 45–50, 196–197;

SLS 40–42; see also surface finish

Powders: polymer 39, 211; metal

Powder Bed Fusion 208–212, 215–216, 219,

228–230; see also selective laser sintering;

multi jet fusion; selective laser melting

Powder coating 232–233

Pre-processing 38–40, 224–232

Process parameters 33–35, 218–222, 225–232

Product innovation 116–119

Prosthetics 131, 137–138, 176–183; see also

medical devices

Prosumer 130, 261

Prototype see rapid prototyping

Quality control 127, 129, 255

Rapid prototyping 71–73, 146–147, 184–186,

189–190

Rapid tooling 91

Recycling 101, 246–248

Repair 246–247

Resin 22–23, 100–101; see also material jetting;

vat photopolymerisation

Role of the designer 267–273

Safety 81–85, 216

Scalable systems of supply 133–137

Scenarios 55–66, 67–69, 93–94, 96–97, 119–120,

122–123, 142

Segmentation 131, 184

Selective Laser Sintering (SLS) 18–20, 36–43,

154–157, 161–162, 178–180, 210–212

Selective Laser Melting (SLM) / Direct Metal

Laser Sintering (DMLS) 44–51, 147–149, 160,

194–197, 215–216

Service bureau 20, 44–45, 139,

226

Sheet lamination 209

Slicing 33–36, 40, 231–232; see also process

parameters

Society 5.0 253–254; responsibility 257–260

Spare parts see digital inventory

Splints 178–180

Sporting products see bicycles, helmets, surf

fins

Standards (e.g., ISO/ASTM) 15–18, 30

Start-up 98, 122, 130, 146–147, 184–186

Stereolithography (SLA) 208

STL file 26–28, 224-225; see also file

Supply chain 89, 125, 139–140; see also digital

inventory; distributed manufacturing

Support material 80, 221–222, 226–227; metal

46–49, 200–203, 215–216; polymer 21,

213–214, 240; see also orientation

Surface finish 21–22, 232–238; see also bead

blasting; hydrographics; painting; polishing;

vapour smoothing

Surface quality 226; see also layer thickness;

orientation; surface finish

Surf fins 197–199

Surgical training 186–188

Sustainability 244–265; future 258–260; invested

objects 249–252; product service system

245–246; temporary products 246–248

Technology adoption 52–66, 69–71, 92–93

Test pieces 49–50, 230

Tolerances 221–222, 225; SLS 41, 43

Topology optimisation 107–108, 111, 147–149,

188–189

Tumbling 235–236

User-centred design 152, 178, 180–183, 264,

271–273

Vapour smoothing 234–235

Vat Photopolymerisation 23, 208; see also digital

light processing; stereolithography

Voxel 24

VRML file 29, 223; see also file

Wall thickness 219–220

Waste 101, 249, 261–262, 264; see also support

material

Wood 3D printing 160–161, 245

Workflow 26–43, 199–204

Workforce development / upskilling 69–71,

92–93

X3D file see VRML

,#3D,#Printing,#3D_Printing,#3D-Printing,#3DPrinting,#الطباعة_ثلاثية_الأبعاد,

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل كتاب 3D Printing for Product Designers

رابط مباشر لتنزيل كتاب 3D Printing for Product Designers

|

|