Admin

مدير المنتدى

عدد المساهمات : 18724

التقييم : 34706

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

|  موضوع: بحث بعنوان Gearbox Tooth Cut Fault Diagnostics Using Acoustic Emission and Vibration Sensors - A Comparative Study موضوع: بحث بعنوان Gearbox Tooth Cut Fault Diagnostics Using Acoustic Emission and Vibration Sensors - A Comparative Study  الخميس 15 سبتمبر 2022, 4:18 am الخميس 15 سبتمبر 2022, 4:18 am | |

|

أخواني في الله

أحضرت لكم

بحث بعنوان

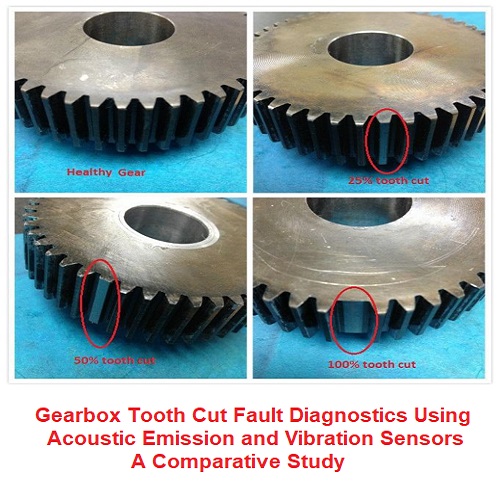

Gearbox Tooth Cut Fault Diagnostics Using Acoustic Emission and Vibration Sensors - A Comparative Study

Yongzhi Qu 1, David He 1,*, Jae Yoon 1, Brandon Van Hecke 1, Eric Bechhoefer 2

and Junda Zhu 3

1 Department of Mechanical and Industrial Engineering, University of Illinois at Chicago,

Chicago, IL 60607, USA; E-Mails: yqu5@uic.edu (Y.Q.); jyoon52@uic.edu (J.Y.);

bvanhe2@uic.edu (B.V.H.) 2

Green Power Monitoring Systems, LLC, Essex Junction, VT 05452, USA;

E-Mail: eric@gpms-vt.com

3 Renewable NRG Systems, Hinesburg, VT 05461, USA; E-Mail: jz@renewablenrgsystems.com

و المحتوى كما يلي :

Abstract: In recent years, acoustic emission (AE) sensors and AE-based techniques have

been developed and tested for gearbox fault diagnosis. In general, AE-based techniques

require much higher sampling rates than vibration analysis-based techniques for gearbox

fault diagnosis. Therefore, it is questionable whether an AE-based technique would give a

better or at least the same performance as the vibration analysis-based techniques using the

same sampling rate. To answer the question, this paper presents a comparative study for

gearbox tooth damage level diagnostics using AE and vibration measurements, the first

known attempt to compare the gearbox fault diagnostic performance of AE- and vibration

analysis-based approaches using the same sampling rate. Partial tooth cut faults are seeded

in a gearbox test rig and experimentally tested in a laboratory. Results have shown that the

AE-based approach has the potential to differentiate gear tooth damage levels in

comparison with the vibration-based approach. While vibration signals are easily affected

by mechanical resonance, the AE signals show more stable performance.

Keywords: gearbox faults; diagnostics; acoustic emission sensor; vibration sensor

Conclusions

Previous research has showed that AE sensor-based approaches using a sampling rate that is

comparable to that of vibration analysis gave good gear fault diagnostic results. However, it is

questionable whether an AE-based technique would give a better or at least the same performance as

the vibration analysis-based techniques using the same sampling rate. To answer the question, this

paper presented a comparative study for gearbox tooth damage level diagnostics using AE and

vibration measurements. Three different levels of tooth cut faults were artificially created and tested on

a notational split torque gearbox in a laboratory. For the AE-based gear fault diagnostic approach, a

hardware frequency convertor based on heterodyne technique was used for AE data collection. Both

the AE signals and vibration signals were collected with the same sampling rate of 100 kHz. Time

synchronous averaging was applied to both types of signals. Condition indicators were then calculated

respectively for AE and vibration signals. Experimental results were provided and explained. Based on

the experimental results, the following conclusions can be drawn:

1. AE signals could be sampled at 100 kHz while maintaining the capability of

distinguishing tooth damage levels using TSA RMS and P2P.

2. AE signals are insensitive to mechanical background noise and mechanical resonance.

Therefore, AE signals have the potential to provide better condition indicators for gear

fault diagnosis.

3. Vibration signal condition indicators are not consistent with gear tooth damage level.

Vibration is less sensitive than AE to small tooth damage in the low speed range.

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل بحث بعنوان Gearbox Tooth Cut Fault Diagnostics Using Acoustic Emission and Vibration Sensors - A Comparative Study

رابط مباشر لتنزيل بحث بعنوان Gearbox Tooth Cut Fault Diagnostics Using Acoustic Emission and Vibration Sensors - A Comparative Study

|

|