Admin

مدير المنتدى

عدد المساهمات : 18745

التقييم : 34763

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

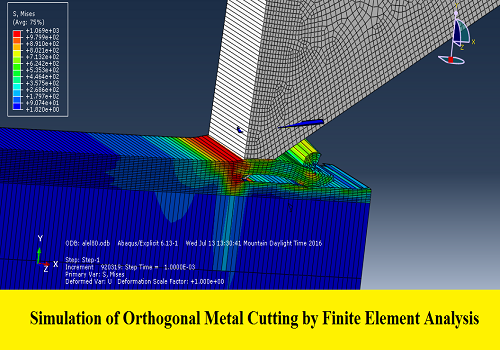

|  موضوع: رسالة ماجستير بعنوان Simulation of Orthogonal Metal Cutting by Finite Element Analysis موضوع: رسالة ماجستير بعنوان Simulation of Orthogonal Metal Cutting by Finite Element Analysis  السبت 16 أغسطس 2014, 11:59 am السبت 16 أغسطس 2014, 11:59 am | |

|

أخوانى فى الله

أحضرت لكم رسالة ماجستير بعنوان

Simulation of Orthogonal Metal Cutting by Finite Element Analysis

A THESIS SUBMITTED TO

THE GRADUATE SCHOOL OF NATURAL AND APPLIED SCIENCES

OF

THE MIDDLE EAST TECHNICAL UNIVERSITY

BY

HALİL BİL

IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF

MASTER OF SCIENCE

IN

THE DEPARTMENT OF MECHANICAL ENGINEERING

ويتناول الموضوعات الأتية :

TABLE OF CONTENTS

Abstract ... iii

Dedication vii

Acknowledgements . viii

Table of Contents ix

List of Tables .. xii

List of Figures .. xiii

List of Symbols and Abbreviations . xviii

CHAPTERS

1 INTRODUCTION . 1

1.1 Introduction . 1

1.2 Aim and Scope of the Study .. 4

1.3 Finite Element Models and Experiments 5

1.4 Content of this Study .. 6

2 LITERATURE SURVEY . 7

2.1 Introduction . 7

2.2 Chip Formation and Nomenclature . 7

2.3 Shear Zone Models . 15

2.4 Shear Angle Relationships . 16

2.4.1 Merchant's Relationship 17

ix2.4.2 Lee and Shaffer's Relationship ......18

2.4.3 Oxley's Relationship .18

2.4.4 Other Relationships 18

2.5 Friction on the Rake Face of a Cutting Tool .19

2.6 The Shear Stress in Shear Zone During Metal Cutting ..21

2.7 Numerical Approach .24

2.7.1 Steady State Solutions ..24

2.7.2 Solutions for Continuous Chip Formation 29

2.7.3 Solutions for Transient Chip Formation ...29

2.7.4 Solutions for Transient and Continuous Chip Formation 31

2.8 Conclusion 38

3 EXPERIMENTAL WORK .39

3.1 Introduction 39

3.2 Orthogonal Cutting 40

3.3 Workpiece Material 41

3.4 Test Setup ...42

3.5 Cutting Experiments Performed in This Work ..49

3.6 Compression Test ...50

4 NUMERICAL MODEL OF ORTHOGONAL METAL CUTTING.. 53

4.1 Introduction 53

4.2 Finite Element Models ..54

4.2.1 Finite Element Model with MSC.Marc ..54

4.2.2 Finite Element Model with Deform2D ..63

4.2.3 Finite Element Model with Thirdwave AdvantEdge .66

4.3 Comparison of Finite Element Models ..71

x5 RESULTS AND COMPARISON .72

5.1 Introduction 72

5.2 Comparison with Analytical Solutions ..75

5.3 Comparison of Chip Geometry ..77

5.4 Comparison of Cutting Forces ..92

5.5 Comparison of Thrust Forces .96

5.6 Comparison of Simulation with the Experimental Results from

Literature ...100

6 DISCUSSION AND CONCLUSION ..104

6.1 Introduction 104

6.2 Effect of Friction ...105

6.3 Effect of Material Modeling .106

6.4 Effect of Chip Separation Criterion .107

6.5 Computational Aspects ..108

6.6 Conclusion 109

6.7 Recommendation for Future Work .. 110

References 112

xiLIST OF TABLES

3.1 Chemical composition of C15 steel in weight percent. ...41

3.2 Mechanical and thermal properties of the workpiece

material, C15 steel ....42

3.3 Specifications of the Topcon Universal Measuring Microscope. 47

3.4 Cutting conditions at which experiments were performed. .49

4.1 Comparison of three commercial codes. 71

5.1 Simulations were done under four different cutting conditions. 72

5.2 Experimental results of chip geometry parameters .78

5.3 Chip geometry results with MSC.Marc. 78

5.4 Chip geometry results from Deform2D. 81

5.5 Chip geometry results from Thirdwave AdvantEdge. ...84

5.6 Cutting conditions for the chip geometry verification. ...89

5.7 Experimentally measured cutting force results. ...92

5.8 Predicted cutting force results from MSC.Marc. 92

5.9 Predicted cutting force results from DEFORM2D. .93

5.10 Predicted cutting force results from Thirdwave AdvantEdge. ...94

5.11 Experimentally measured thrust force results. ...96

5.12 Predicted thrust force results estimated by MSC.Marc. ...97

5.13 Predicted thrust force results from DEFORM2D. 98

5.14 Predicted thrust force results from Thirdwave AdvantEdge. ..99

5.15 Experimental and Simulation results of Movahhedy and Altintas. .101

5.16 Comparison with literature (m=0.1). ..101

5.17 Comparison with literature (m=0.7). ..101

xiiLIST OF FIGURES

2.1 Orthogonal and Oblique Cutting ... 8

2.2 Chip samples produced by quick stop techniques . 9

2.3 Some of the variables in orthogonal cutting .. 10

2.4 Assumed shape of deformation zone in cutting ..... 11

2.5 A photomicrograph of orthogonal cutting operation

where thin shear plane is approached 12

2.6 An illustration of the mechanism of discontinuous chip formation .. 12

2.7 Idealized picture of built-up edge (B.U.E) formation 13

2.8 Typical shape of the stress-strain relationship for

a metal under the action of a tensile stress 14

2.9 Shear zone types 16

2.10 Variables used in shear angle relationships ... 17

2.11 Dependence of friction force to the normal force .. 20

2.12 Frictional shear stress distribution on rake face of the tool ... 21

2.13 Pre-Flow region . 22

2.14 Model by Strenkowski and Kyoung-Jin Moon .. 25

2.15 Model by Stevenson, Wright and Chow 27

2.16 Initial and deformed of the model by Arola and Ramulu .. 30

2.17 Model developed Carroll and Strenkowski ... 31

2.18 Estimated chips at different rake angles by Carroll and Strenkowski ... 32

2.19 The initial finite element mesh, configuration of the cutting

tool and dimensions of the elements developed by Shih ... 34

xiii2.20 Remeshing module used by Ceretti, Lucchi and Altan . 35

2.21 Oxley’s theory and its simplified flow chart . 36

2.22 Results of the work done by Borouchaki, Cherouat,

Laug and Saanouni 37

3.1 Schematic representation of orthogonal cutting and

velocity diagram 40

3.2 Orthogonal turning operation on a lathe 41

3.3 Test Setup .. 42

3.4 Lathe tool dynamometer setup .. 43

3.5 Analog display of the dynamometer . 44

3.6 Calibration of the dynamometer 45

3.7 Calibration curve for cutting force 45

3.8 Calibration curve for thrust force .. 46

3.9 Contact length on the rake face of the tool 47

3.10 Microscope by which the thicknesses of chips were measured . 48

3.11 A sample microscope view while measuring thickness 48

3.12 Comparison of experimental and simulated

compressed specimens ... 51

3.13 Comparison of punch displacement – punch force diagram . 52

4.1 Finite element model of MSC.Marc .. 54

4.2 Quadrilateral element 55

4.3 Distribution of generated heat due to friction 57

4.4 Workpiece flow curve for strain-rate of 40 (s-1) ... 58

4.5 Workpiece flow curve for strain-rate of 8 (s-1) . 59

4.6 Workpiece flow curve for strain-rate of 1.6 (s-1) .. 59

4.7 Effect of strain-rate on the flow curves . 60

4.8 Step function frictional stress and approximation by Equation 4.5 ... 61

xiv4.9 Separation of chip from the workpiece by continuous remeshing 63

4.10 Finite element model of Deform2D .. 64

4.11 Element erase due to damage via remeshing in Deform2D...................... 65

4.12 Finite element model of Third Wave Systems AdvantEdge . 67

4.13 Six-noded triangular element . 69

5.1 A typical diagram of cutting force versus increment number ... 73

5.2 Effect of contact penetration value 74

5.3 Effect of penetration check method on the results . 74

5.4 Rake, Shear and Friction angle for an orthogonal cut ... 76

5.5 Allowable slip-line model solutions for rake angle of 20° 76

5.6 Allowable slip-line model solutions for rake angle of 25° 77

5.7 Shear angle can be found from strain-rate distribution . 79

5.8 Effect of friction factor on the chip thickness results obtained

by MSC.Marc 80

5.9 Effect of friction factor on the shear angles obtained by

MSC.Marc calculated from chip thickness results. ... 80

5.10 Effect of friction factor on the contact length results

by MSC.Marc 81

5.11 Effect of friction factor on the chip thickness results

by Deform2D . 82

5.12 Effect of friction factor on the shear angles obtained by

Deform2D calculated from chip thickness results. .... 83

5.13 Effect of friction factor on the contact length results by Deform2D . 83

5.14 Effect of friction factor on the chip thickness results by Thirdwave

AdvantEdge 85

5.15 Effect of friction factor on the shear angles obtained by Thirdwave

AdvantEdge calculated from chip thickness results .. 85

xv5.16 Effect of friction factor on the contact length

by Thirdwave AdvantEdge 86

5.17 Comparison of chip thickness results from three

codes with experiments .. 87

5.18 Shear angles obtained by three codes from chip thickness estimation...... 88

5.19 Comparison of contact length results from three

codes with experiments .. 90

5.20 Simulated chip geometries from three commercial

codes at 20° rake angle .. 91

5.21 Simulated chip geometries with three commercial

codes at 25° rake angle .. 93

5.22 Effect of Friction on the cutting force results of MSC.Marc . 94

5.23 Effect of friction on the cutting force results of Deform2D .. 95

5.24 Effect of friction on the cutting force results of

Thirdwave AdvantEdge . 95

5.25 Comparison of cutting forces estimated by

three codes and experiments .. 96

5.26 Forces acting on the tool .... 97

5.27 Effect of friction factor on the thrust force prediction of MSC.Marc .... 98

5.28 Effect of friction factor on the thrust force prediction

of Deform2D .. 99

5.29 Effect of friction factor on the thrust force

by Thirdwave AdvantEdge 100

5.30 Comparison of thrust forces estimated by three

codes and experiments ... 102

5.31 Comparison of cutting and thrust forces obtained

by MSC.Marc with experiment from literature . 102

xvi5.32 Comparison of shear angle obtained by MSC.Marc

with experiment from literature . 103

5.33 Comparison of contact length obtained by MSC.Marc

with experiment from literature . 103

5.34 Comparison of contact length estimated by MSC.Marc

with experiment from literature .

6.1 Crack generated by remeshing

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل رسالة ماجستير بعنوان Simulation of Orthogonal Metal Cutting by Finite Element Analysis

رابط مباشر لتنزيل رسالة ماجستير بعنوان Simulation of Orthogonal Metal Cutting by Finite Element Analysis

|

|